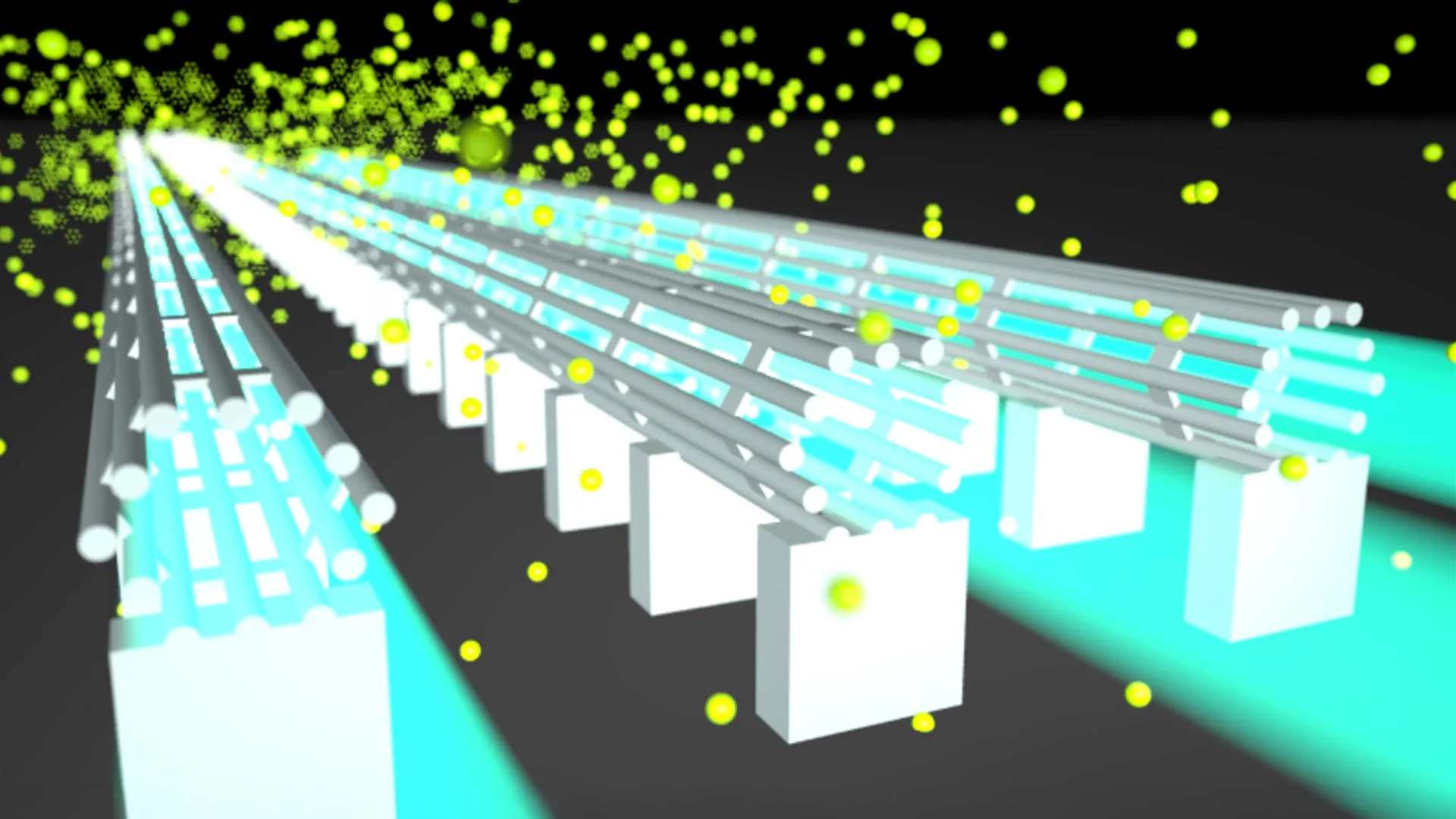

A pivotal study, recently published in the esteemed journal Light: Science & Applications, details a significant leap forward in quantum memory technology. The research team has unveiled a novel type of quantum memory constructed from intricately designed 3D-nanoprinted structures, aptly termed "light cages." These remarkable structures are filled with atomic vapor, ingeniously bringing both light and atoms together onto a single chip. This integrated platform is meticulously engineered for scalability and seamless integration into the complex landscape of quantum photonic systems, paving the way for more robust and expansive quantum networks.

The Revolutionary Design of Light Cages: A Paradigm Shift in Quantum Memory Fabrication

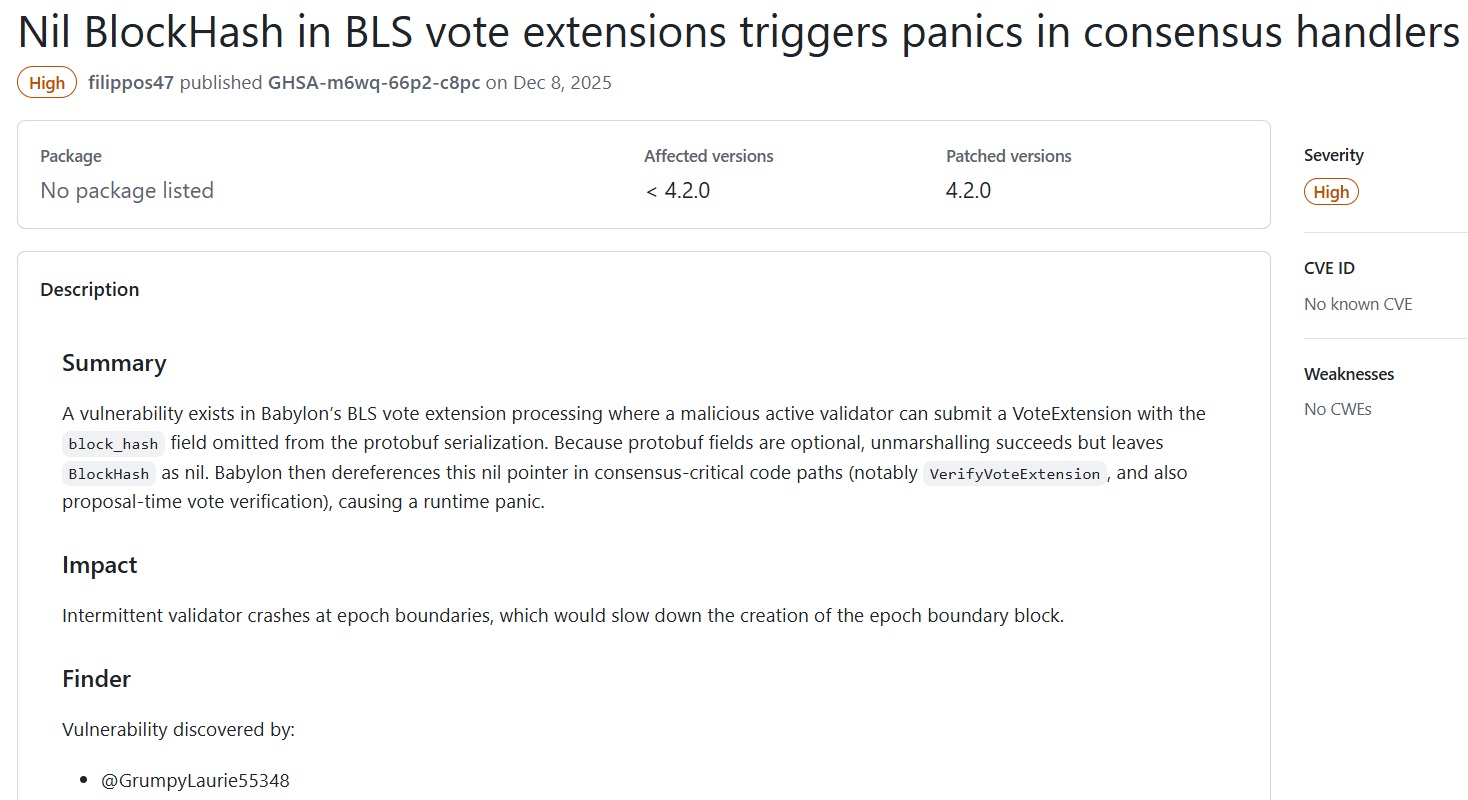

What sets these light cages apart from conventional quantum memory approaches is their innovative design and fabrication process. Light cages are essentially hollow-core waveguides, precisely engineered to confine light within their core while simultaneously providing open access for atomic vapor. This distinctive architecture offers a substantial advantage over traditional hollow-core fibers, which can notoriously take months to effectively fill with atomic vapor. In stark contrast, the open and accessible nature of the light cage’s internal structure facilitates the rapid diffusion of cesium atoms into the core. This accelerated filling process can be completed in a mere few days, a dramatic reduction in time, all without compromising the critical optical performance of the device.

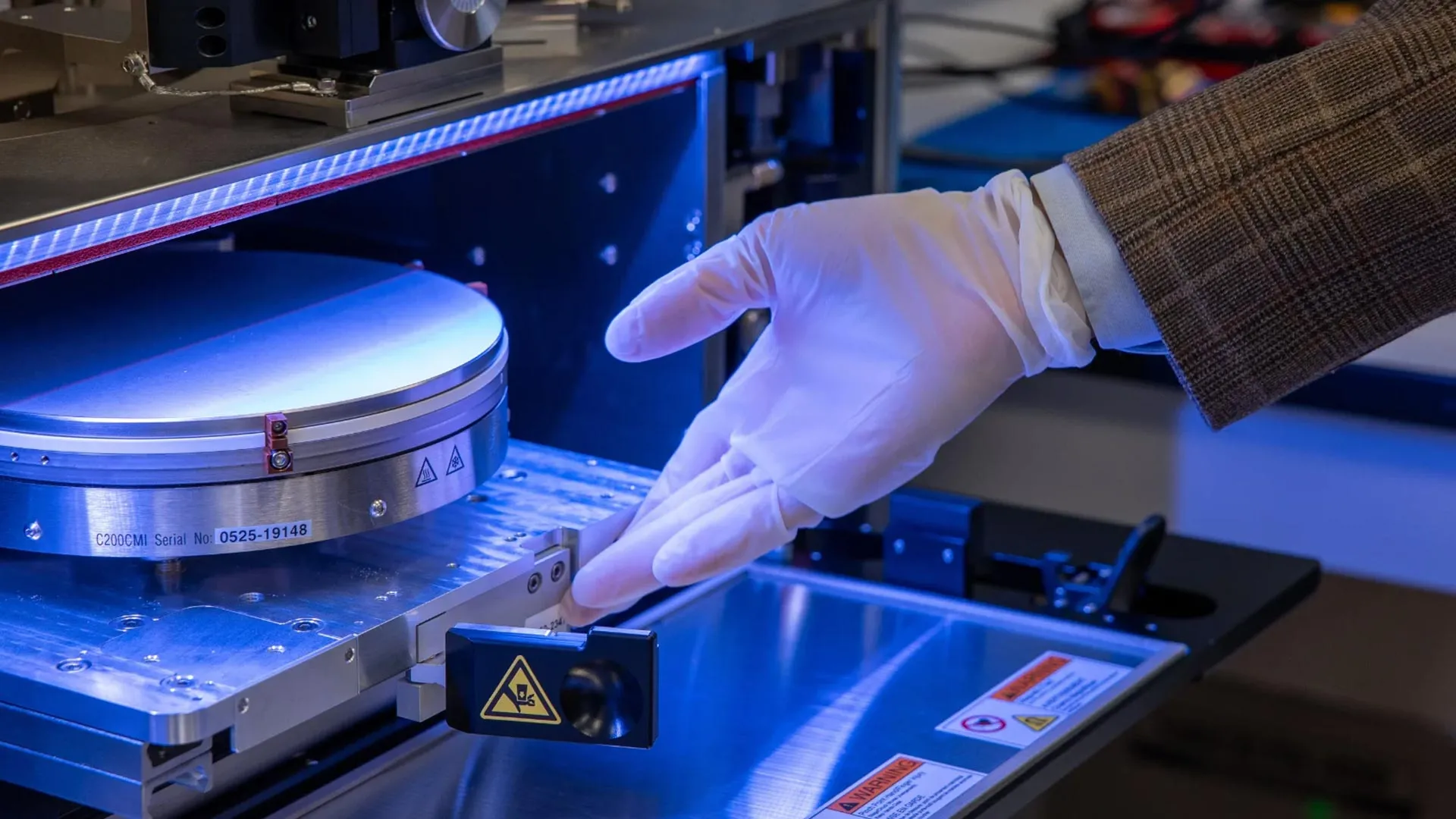

The fabrication of these intricate light cages is achieved through a sophisticated technique known as two-photon polymerization lithography, utilizing commercially available 3D printing systems. This advanced additive manufacturing approach empowers researchers to directly print highly complex hollow-core waveguides onto silicon chips with an unprecedented level of precision. To ensure the longevity and integrity of these delicate structures, particularly when interacting with cesium atoms, the waveguides are meticulously coated with a protective layer. Rigorous testing has confirmed the remarkable durability of these coatings, demonstrating no signs of degradation even after an extended period of five years of continuous operation. This exceptional long-term stability is a testament to the robustness of the system and its potential for real-world applications.

The research team articulated the significance of their creation, stating, "We created a guiding structure that allows quick diffusion of gases and fluids inside its core, with the versatility and reproducibility provided by the 3D-nanoprinting process. This enables true scalability of this platform, not only for intra-chip fabrication of the waveguides but also inter-chip, for producing multiple chips with the same performance." This quote underscores the core advantages of their innovation: rapid material ingress, inherent versatility, and the reproducible precision afforded by advanced 3D printing.

Transforming Light into Stored Quantum Information: The Mechanism of Light Cage Quantum Memories

The operational principle of these light cage quantum memories is elegantly efficient. When incoming light pulses enter the light cages, they are converted with remarkable efficiency into collective excitations of the surrounding atomic vapor. This effectively "stores" the quantum information encoded in the light within the atoms. After a precisely controlled storage duration, a dedicated control laser is employed to reverse this process, releasing the stored light exactly when and where it is needed. In a crucial experimental demonstration, the researchers successfully achieved the storage of extremely weak light pulses, containing as few as a handful of photons, for durations of several hundred nanoseconds. The team is confident that this technology can be further refined to achieve the storage of single photons for extended periods, potentially reaching many milliseconds.

A further significant milestone achieved in this research is the successful integration of multiple light cage memories onto a single chip. This chip was then housed within a cesium vapor cell, a controlled environment for optimal operation. The performance of these integrated memories was rigorously assessed, revealing that different light cages, despite being fabricated with the same design, exhibited nearly identical storage performance across two distinct devices residing on the same chip. This extraordinary level of consistency is an absolutely critical prerequisite for the development of scalable quantum systems, where uniform performance across numerous components is paramount.

This exceptional reproducibility is directly attributable to the exquisite precision of the 3D-nanoprinting process. The fabrication process ensures that variations within a single chip are minimized to less than 2 nanometers, while the differences between separate chips remain under an impressive 15 nanometers. Such meticulous control is not merely an academic achievement; it is fundamental for enabling techniques like spatial multiplexing. Spatial multiplexing is a powerful method that could dramatically increase the number of quantum memories operating concurrently on a single device, thereby significantly enhancing the overall processing power and communication capacity of quantum systems.

Profound Implications for the Future of Quantum Networks and Computing

The development of light cage quantum memories directly addresses several persistent and significant challenges that have historically hindered the advancement of quantum technologies. In the context of quantum repeater networks, these novel memories are poised to revolutionize long-distance quantum communication. They can synchronize multiple single photons arriving at different times, thereby vastly improving the efficiency of entanglement swapping protocols and, consequently, the overall success rate of transmitting quantum information over vast distances. Furthermore, within the realm of photonic quantum computing, these memories serve as essential components, providing the precisely controlled delays required for critical feed-forward operations in measurement-based quantum computing architectures.

Beyond their technical capabilities, the light cage platform also stands out for its remarkable practicality and operational simplicity. In stark contrast to many competing quantum memory technologies that necessitate cryogenic cooling or complex atom-trapping setups, this system operates comfortably slightly above room temperature. This reduced operational complexity makes the system significantly easier to deploy and maintain, while simultaneously offering a higher bandwidth per memory mode. The inherent ability to produce a large number of identical quantum memories on a single chip represents a clear and achievable pathway toward the realization of large-scale quantum photonic integration, a critical goal for the future of quantum technology.

The inherent flexibility of the fabrication process opens up exciting possibilities for further integration. The technology can potentially be seamlessly combined with direct fiber coupling techniques and existing photonic components, facilitating its incorporation into established quantum infrastructure. These multifaceted advantages position light cage quantum memories as a leading contender for building the foundational elements of future quantum communication networks.

A Scalable and Promising Path Forward for Quantum Advancement

The development of these innovative light cage quantum memories marks a truly significant milestone in the field of quantum photonic research. By ingeniously merging cutting-edge 3D-nanoprinting techniques with the fundamental principles of quantum optics, the research team has successfully engineered a system that is both compact and highly scalable. This breakthrough holds immense promise for accelerating the arrival of practical quantum networks and ushering in an era of more powerful and sophisticated quantum computers, ultimately reshaping the landscape of information technology and scientific discovery.