However, a groundbreaking development from researchers at the NYU Tandon School of Engineering offers a compelling and sustainable solution. In a paper published in the prestigious journal ACS Applied Materials & Interfaces, the team unveils a novel approach that utilizes environmentally friendly quantum dots to detect infrared light, completely circumventing the need for harmful heavy metals. This innovation promises to revolutionize the infrared detector industry, making advanced imaging technology more accessible, affordable, and environmentally responsible.

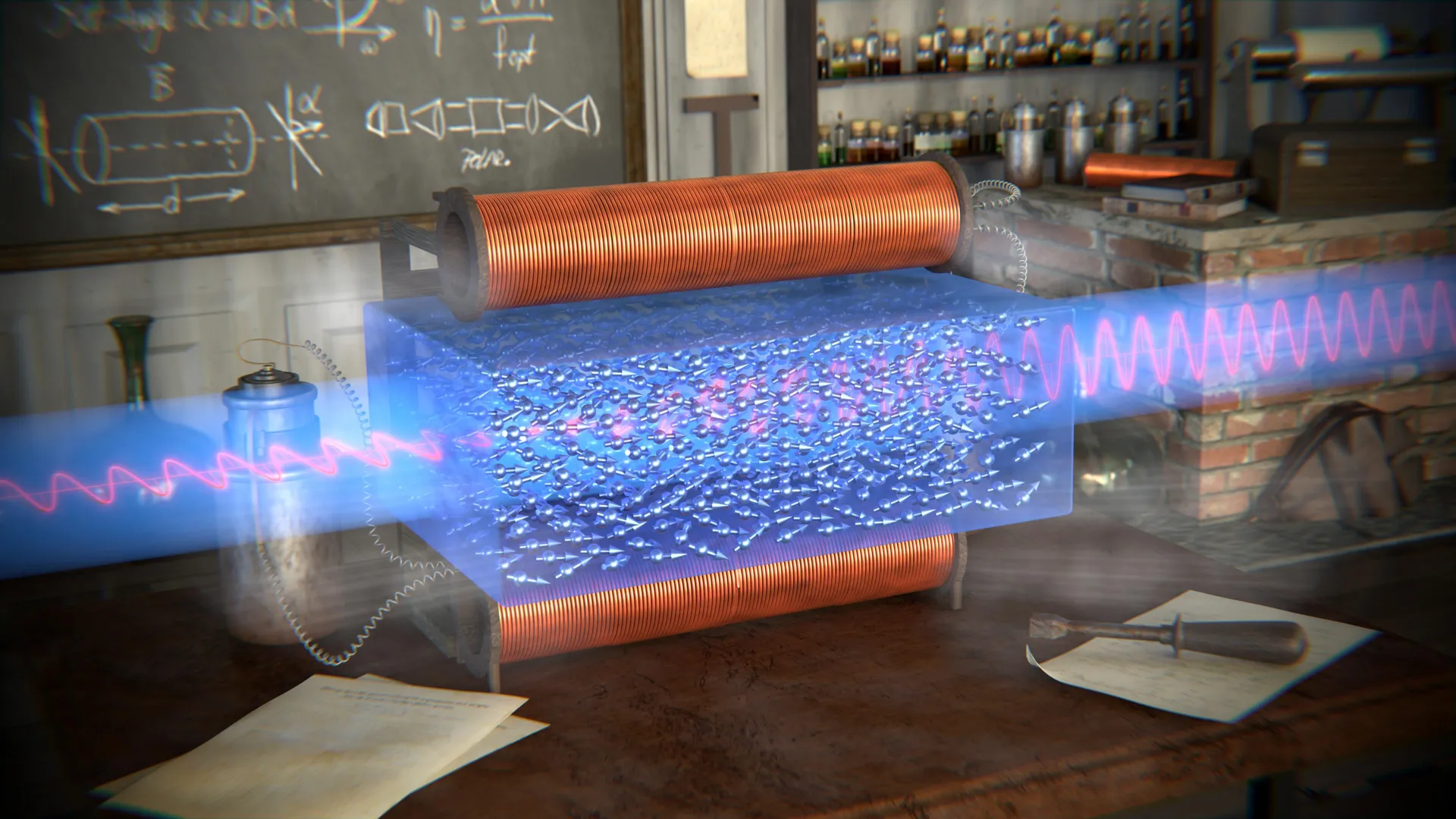

The core of this breakthrough lies in the use of colloidal quantum dots. These microscopic semiconductor particles represent a significant departure from the age-old, labor-intensive, and prohibitively expensive methods traditionally employed in the fabrication of infrared detectors. Historically, creating these detectors involved an almost painstaking atomic-level assembly process. Imagine meticulously placing individual atoms across the pixels of a detector, a task akin to constructing a microscopic puzzle under extreme magnification. This ultra-precise, step-by-step approach is not only incredibly slow but also inherently costly, severely limiting production scalability.

In stark contrast, the NYU Tandon team’s quantum dots are synthesized entirely in a liquid solution, a process they aptly liken to "brewing ink." This "quantum ink" can then be deposited onto substrates using scalable coating techniques. These techniques are remarkably similar to those used in high-volume manufacturing processes, such as the roll-to-roll printing used for producing packaging materials or newspapers. This fundamental shift from intricate, piece-by-piece assembly to a fluid, solution-based processing method offers a dramatic reduction in manufacturing costs. The implications are profound, opening the door for widespread commercial applications that were previously economically unfeasible.

Ayaskanta Sahu, an associate professor in the Department of Chemical and Biomolecular Engineering (CBE) at NYU Tandon and the senior author of the study, vividly described the industry’s predicament. "The industry is facing a perfect storm where environmental regulations are tightening just as demand for infrared imaging is exploding," he stated. "This creates real bottlenecks for companies trying to scale up production of thermal imaging systems." Sahu’s observation underscores the urgent need for innovative solutions that can meet both performance demands and environmental imperatives.

Beyond the material itself, the researchers also tackled another significant hurdle: ensuring the quantum dot ink possessed sufficient electrical conductivity to effectively relay signals from the detected infrared light. This challenge was met through a sophisticated technique known as solution-phase ligand exchange. This process allows for the precise tailoring of the quantum dot’s surface chemistry. By modifying these surface properties, the researchers can significantly enhance the quantum dots’ performance within electronic devices. A key advantage of this solution-based approach is its ability to yield smooth, uniform coatings in a single step. This is a critical factor for scalable manufacturing, as it avoids the cracking or unevenness often associated with traditional fabrication methods.

The performance metrics of the resulting quantum dot-based infrared detectors are nothing short of remarkable. They demonstrate an impressive response time to infrared light, operating on the microsecond timescale. For perspective, this is hundreds of times faster than the blink of a human eye. Furthermore, these detectors possess the sensitivity to detect signals as faint as a nanowatt of light, indicating their potential for capturing subtle thermal variations.

Shlok J. Paul, a graduate researcher and the lead author of the study, expressed his excitement about the material’s potential. "What excites me is that we can take a material long considered too difficult for real devices and engineer it to be more competitive," he said. Paul also highlighted the future potential of this technology. "With more time this material has the potential to shine deeper in the infrared spectrum where few materials exist for such tasks." This suggests that the current development is just the tip of the iceberg, with further research poised to unlock even more advanced infrared detection capabilities.

This recent work builds upon a foundation of earlier research from the same lead researchers. Previously, they had developed novel transparent electrodes utilizing silver nanowires. These electrodes are crucial components of infrared camera systems because they are highly transparent to infrared light, allowing it to reach the detector, while simultaneously efficiently collecting the electrical signals generated by the detector. The combination of these new quantum dot detectors and the previously developed transparent electrodes addresses the two most critical components of an infrared imaging system. The quantum dots provide the environmentally compliant sensing capability, while the transparent electrodes handle the essential tasks of signal collection and processing.

This synergistic approach is particularly well-suited for addressing the challenges associated with large-area infrared imaging arrays. Such arrays are essential for applications requiring high-performance detection across wide fields of view, as well as for accurately reading out signals from millions of individual detector pixels. The transparent electrodes are vital in these systems, as they not only allow the incoming infrared light to reach the quantum dot detectors but also provide the necessary electrical pathways for extracting and processing the signals. This integrated solution paves the way for more sophisticated and versatile infrared imaging systems.

Professor Sahu emphasized the practical implications of their research, noting, "Every infrared camera in a Tesla or smartphone needs detectors that meet environmental standards while remaining cost-effective. Our approach could help make these technologies much more accessible." This statement underscores the potential of their quantum ink to democratize access to advanced infrared imaging, making it a standard feature in a wider range of consumer and industrial products.

While the current performance of these quantum dot detectors, in some specific measurements, may still fall slightly short of the most advanced heavy-metal-based detectors, the researchers are optimistic about the future. They anticipate that continued advancements in quantum dot synthesis techniques and ongoing refinements in device engineering will rapidly bridge this gap. The inherent advantages of cost-effectiveness, environmental sustainability, and scalability offered by their approach provide a powerful impetus for further development.

The paper’s authorship includes not only Sahu and Paul but also Letian Li, Zheng Li, Thomas Kywe, and Ana Vataj, all affiliated with NYU Tandon CBE. The research received crucial support from the Office of Naval Research and the Defense Advanced Research Projects Agency, highlighting the significant national interest in developing advanced and sustainable infrared detection technologies. This collaborative effort and external validation underscore the importance and potential impact of this scientific breakthrough.