This regulatory pressure is creating significant bottlenecks, precisely at a time when the demand for infrared detectors is experiencing an unprecedented surge. Fields such as autonomous driving, where the ability to "see" in low light or fog is paramount for safety, are crying out for more accessible and compliant infrared solutions. Medical imaging, too, stands to benefit immensely from advanced thermal imaging capabilities, offering new diagnostic insights and treatment monitoring. And in the realm of national security, the need for sophisticated surveillance and threat detection remains a constant. However, the very composition of current infrared detectors, often reliant on restricted materials, is hindering progress.

Amidst this perfect storm of tightening environmental mandates and booming demand, a beacon of hope has emerged from the laboratories of NYU Tandon School of Engineering. In a groundbreaking paper published in the prestigious journal ACS Applied Materials & Interfaces, researchers have unveiled a potential solution that promises to revolutionize infrared detection. Their innovative approach harnesses the power of environmentally friendly quantum dots, a novel class of nanomaterials capable of detecting infrared light without the need for mercury, lead, or other hazardous substances that are increasingly falling out of favor.

The true genius of this breakthrough lies in its departure from the age-old, prohibitively expensive, and painstakingly tedious methods of fabricating infrared detectors. Traditional devices are brought to life through ultra-precise, atom-by-atom assembly processes. Imagine painstakingly placing individual atoms across the pixels of a detector, akin to assembling an impossibly intricate puzzle under a high-powered microscope. This method is not only incredibly slow and resource-intensive but also inherently limits scalability and drives up manufacturing costs.

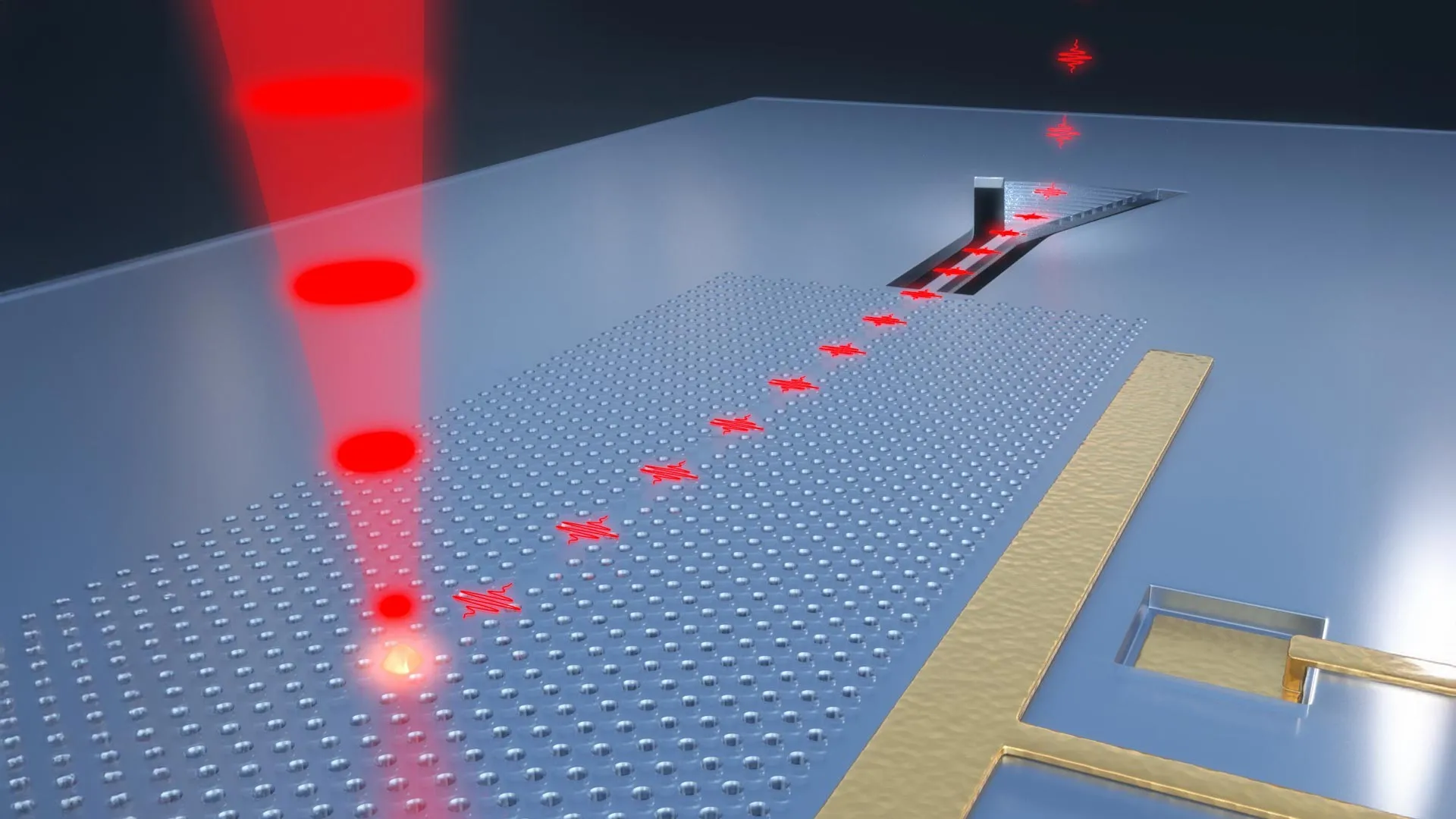

In stark contrast, the NYU Tandon team’s quantum dots are synthesized entirely in solution, a process more akin to brewing an ink than to delicate micro-assembly. This “quantum ink” can then be deposited using scalable coating techniques, reminiscent of the high-speed, roll-to-roll manufacturing processes used to produce everyday items like packaging or newspapers. This fundamental shift from meticulous, piece-by-piece assembly to a fluid, solution-based approach promises to dramatically slash manufacturing costs and, crucially, pave the way for widespread commercial applications that were previously economically unfeasible.

"The industry is facing a perfect storm where environmental regulations are tightening just as demand for infrared imaging is exploding," explained Ayaskanta Sahu, an associate professor in the Department of Chemical and Biomolecular Engineering (CBE) at NYU Tandon and the senior author of the study. "This creates real bottlenecks for companies trying to scale up production of thermal imaging systems. Our work directly addresses this critical need for sustainable and scalable solutions."

Beyond the environmental and manufacturing advantages, the researchers also tackled another significant hurdle: ensuring the quantum dot ink possessed sufficient electrical conductivity to effectively relay signals from the incoming infrared light. This was achieved through an ingenious technique known as solution-phase ligand exchange. This process allows for precise tailoring of the quantum dot surface chemistry, enhancing their performance in electronic devices. A key advantage of this solution-based methodology is its ability to yield smooth, uniform coatings in a single step, a stark contrast to traditional fabrication methods that often result in cracked or uneven films. This uniformity is paramount for achieving high-performance and consistent results in scalable manufacturing.

The resulting infrared detectors, born from this innovative "quantum ink," exhibit remarkable performance characteristics. They demonstrate an impressive response time to infrared light on the microsecond timescale – a speed that dwarfs the human eye’s blink, which occurs hundreds of times slower. Furthermore, these new detectors possess the sensitivity to pick up signals as faint as a nanowatt of light, underscoring their potential for detecting subtle thermal variations.

"What excites me is that we can take a material long considered too difficult for real devices and engineer it to be more competitive," enthused graduate researcher Shlok J. Paul, the lead author of the study. "With continued development, this material has the potential to push the boundaries of infrared detection deeper into the spectrum, where currently very few materials exist for such demanding tasks."

This latest research builds upon a strong foundation of prior work from the same lead researchers. Notably, they had previously developed novel transparent electrodes utilizing silver nanowires. These electrodes are crucial components in infrared camera systems, as they need to be highly transparent to infrared light, allowing it to reach the detector, while simultaneously efficiently collecting the electrical signals generated. Their earlier work addressed this critical aspect of signal collection and processing.

When combined with the newly developed quantum dot ink, these two innovations address the two most significant components of an infrared imaging system. The quantum dots provide the environmentally compliant sensing capability, allowing for the detection of infrared radiation without toxic heavy metals. Simultaneously, the transparent electrodes handle the essential tasks of signal collection and processing, ensuring that the captured information can be accurately relayed.

This synergistic combination holds immense promise for addressing the challenges inherent in large-area infrared imaging arrays. Such arrays, vital for applications like wide-area surveillance or advanced imaging systems, require high-performance detection across vast surfaces and the ability to efficiently read out signals from millions of individual detector pixels. The transparent electrodes, by allowing light to pass through to the quantum dot detectors while providing clear electrical pathways for signal extraction, are instrumental in enabling these complex, large-scale systems.

The implications of this research extend directly to the consumer market. "Every infrared camera in a Tesla or smartphone needs detectors that meet environmental standards while remaining cost-effective," Professor Sahu emphasized. "Our approach could help make these technologies much more accessible. Imagine advanced night vision capabilities becoming standard in everyday devices, or medical diagnostic tools becoming more affordable and widely available."

While the current performance of these quantum dot detectors, in some specific measurements, may still fall slightly short of the absolute best heavy-metal-based detectors, the researchers are optimistic about future advancements. They anticipate that continued progress in quantum dot synthesis techniques and ongoing refinements in device engineering will steadily close this performance gap. The inherent advantages of sustainability, cost-effectiveness, and scalability offered by their quantum ink approach provide a powerful impetus for this ongoing development.

The groundbreaking research was a collaborative effort, with the paper’s authors including Letian Li, Zheng Li, Thomas Kywe, and Ana Vataj, all from NYU Tandon CBE, alongside Sahu and Paul. The project received crucial support from esteemed institutions like the Office of Naval Research and the Defense Advanced Research Projects Agency, underscoring the national significance and strategic importance of this innovative work in pushing the boundaries of infrared technology towards a more sustainable and accessible future.