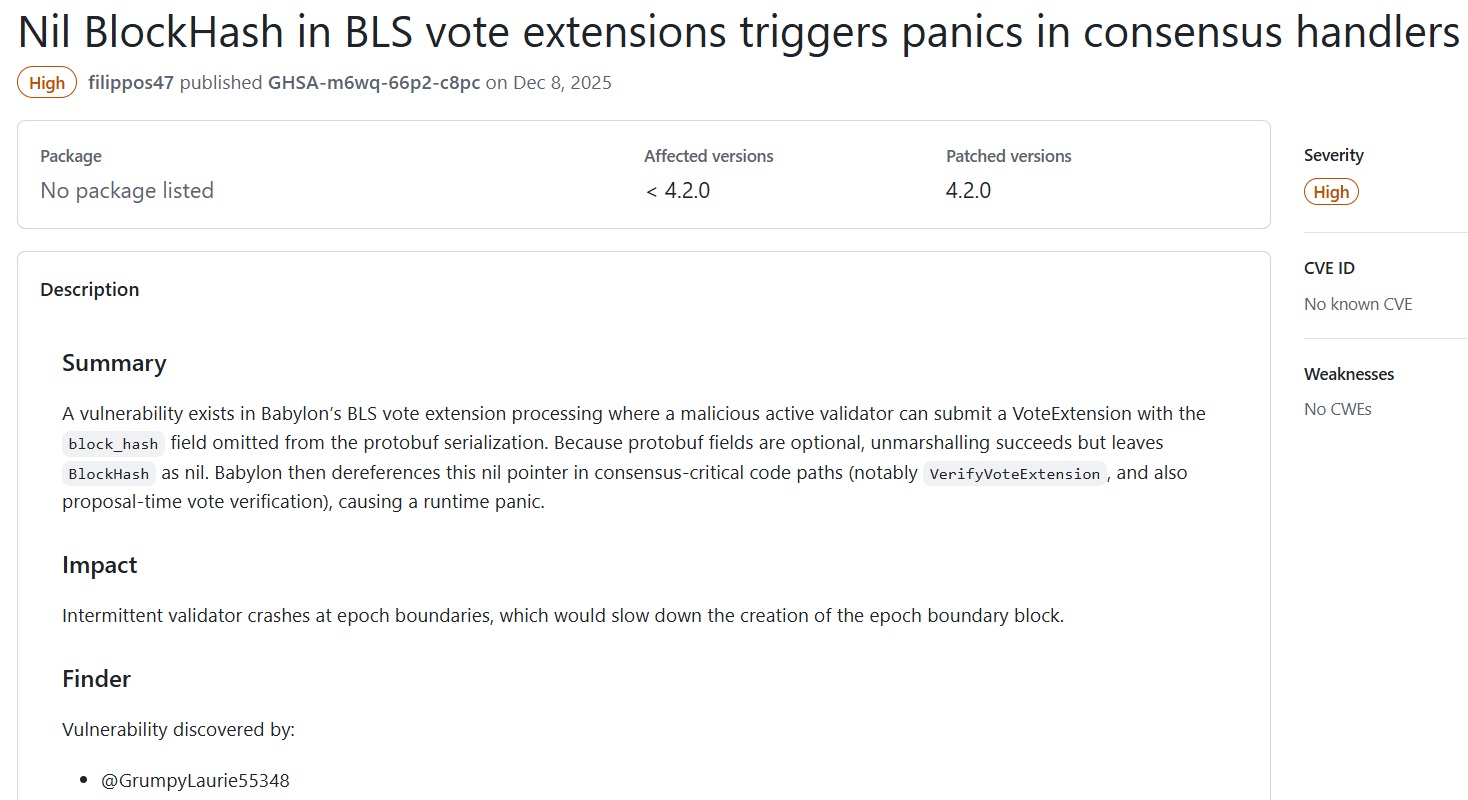

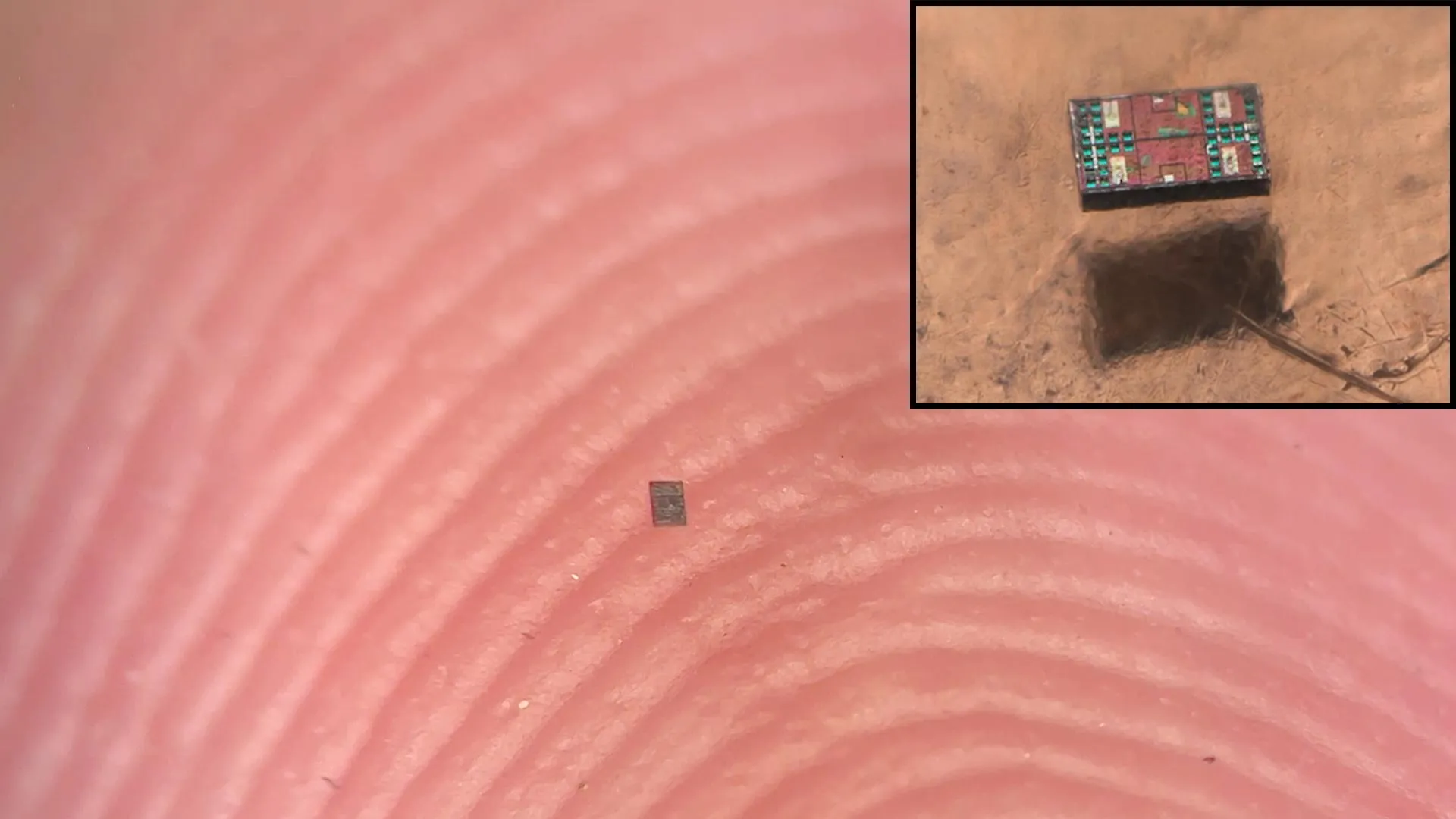

In a groundbreaking leap for miniaturization and artificial intelligence, researchers from the University of Pennsylvania and the University of Michigan have engineered the smallest fully programmable autonomous robots ever conceived. These nearly invisible machines, measuring a mere 200 by 300 by 50 micrometers, are smaller than a grain of salt and possess an astonishing array of capabilities. They can navigate through liquids, perceive their surroundings, make independent decisions, operate for extended periods of months, and astonishingly, cost approximately one cent each to produce. This remarkable achievement, detailed in prestigious journals Science Robotics and the Proceedings of the National Academy of Sciences (PNAS), heralds a new era for robotics, opening up unprecedented possibilities in fields ranging from medicine to advanced manufacturing.

The significance of this breakthrough lies in its defiance of long-standing engineering hurdles. While electronics have shrunk dramatically over the decades, the field of robotics has struggled to keep pace at the sub-millimeter scale. "Building robots that operate independently at sizes below one millimeter is incredibly difficult," explains Marc Miskin, Assistant Professor in Electrical and Systems Engineering at Penn Engineering and the senior author of the papers. "The field has essentially been stuck on this problem for 40 years." The fundamental challenge stems from the drastically altered physics at this microscopic realm. At everyday scales, motion is governed by gravity and inertia, forces dependent on an object’s volume. However, at microscopic dimensions, surface forces like drag and viscosity become overwhelmingly dominant, fundamentally changing how movement occurs. As Miskin aptly describes, "If you’re small enough, pushing on water is like pushing through tar." Conventional robotic designs, with delicate articulated limbs, falter under these conditions, with tiny arms or legs proving fragile and exceedingly difficult to manufacture.

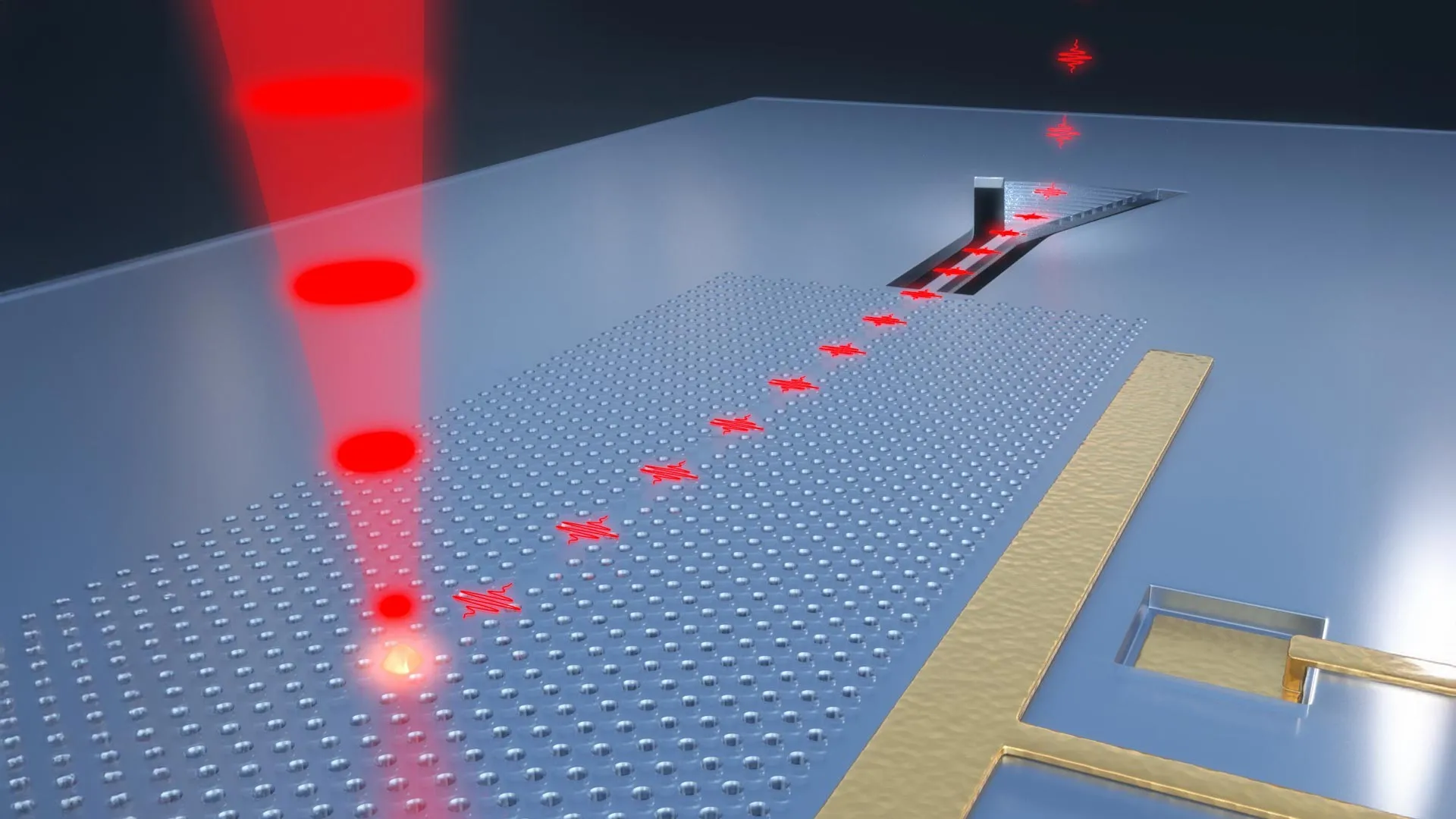

To circumvent these limitations, the research team devised an entirely novel propulsion system that harmonizes with, rather than fights against, the physics of the microscopic world. Unlike larger organisms that propel themselves by pushing water backward, these microscopic robots employ a sophisticated electrokinetic mechanism. They generate an electrical field that subtly nudges charged particles within the surrounding liquid. This movement of ions, in turn, drags nearby water molecules, creating a localized current that propels the robot forward. "It’s as if the robot is in a moving river, but the robot is also causing the river to move," states Miskin. By precisely controlling this electrical field, the robots can alter their direction, traverse intricate paths, and even synchronize their movements in collective formations reminiscent of schooling fish. Their impressive agility allows them to achieve speeds of up to one body length per second. Crucially, this electrode-based propulsion system, devoid of any moving parts, imbues the robots with exceptional durability. They can withstand repeated transfers between samples using a micropipette without sustaining damage. Powered solely by light from an LED, these resilient robots can maintain their operational capabilities for months on end.

However, true autonomy extends beyond mere locomotion. A robot must also possess the capacity to sense its environment, process information, and make decisions. Integrating these essential components onto a chip measuring a fraction of a millimeter presented a formidable challenge, which was expertly addressed by David Blaauw’s team at the University of Michigan. Blaauw’s lab, already renowned for creating the world’s smallest computer, found a perfect synergy with Penn Engineering’s propulsion technology. "We saw that Penn Engineering’s propulsion system and our tiny electronic computers were just made for each other," remarks Blaauw, reflecting on their initial meeting five years prior. The five years of subsequent development were dedicated to overcoming significant hurdles, particularly in power management and computational space.

The power source for these microscopic robots is derived from tiny solar panels, which generate a mere 75 nanowatts of power – over 100,000 times less than what a smartwatch consumes. To harness this minimal energy, the team engineered highly specialized circuits that operate at extremely low voltages, achieving an astonishing power consumption reduction of over 1,000 times. Space constraints were equally stringent, with the solar panels occupying a significant portion of the robot’s surface, leaving scant room for processing hardware. This led to a radical redesign of the robot’s software architecture. "We had to totally rethink the computer program instructions," Blaauw explains. "We condensed what conventionally would require many instructions for propulsion control into a single, special instruction to shrink the program’s length to fit in the robot’s tiny memory space."

These combined innovations have culminated in what the researchers believe to be the first sub-millimeter robot capable of genuine decision-making. The integration of a complete computer, including a processor, memory, and sensors, into such a diminutive package is an unprecedented achievement. This enables the robots to perceive their surroundings and respond independently. Equipped with electronic temperature sensors, they can detect temperature fluctuations as minute as one-third of a degree Celsius. This sensitivity opens avenues for monitoring individual cells, potentially by detecting localized temperature variations indicative of cellular activity.

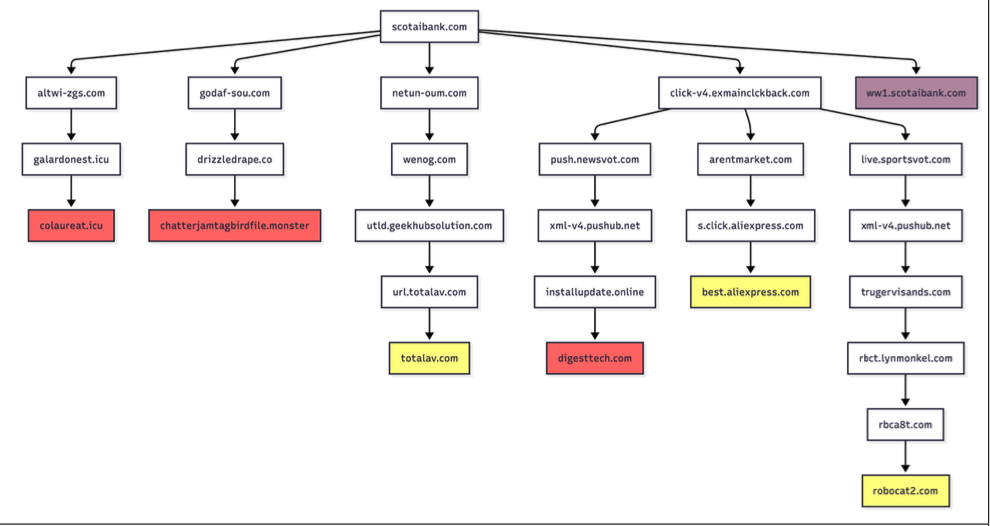

Communicating their findings required another ingenious solution. "To report out their temperature measurements, we designed a special computer instruction that encodes a value, such as the measured temperature, in the wiggles of a little dance the robot performs," says Blaauw. "We then look at this dance through a microscope with a camera and decode from the wiggles what the robots are saying to us. It’s very similar to how honey bees communicate with each other." The same light source that powers the robots also serves as the means to program them. Each robot possesses a unique address, allowing researchers to upload distinct instructions to individual units. "This opens up a host of possibilities," Blaauw adds, "with each robot potentially performing a different role in a larger, joint task."

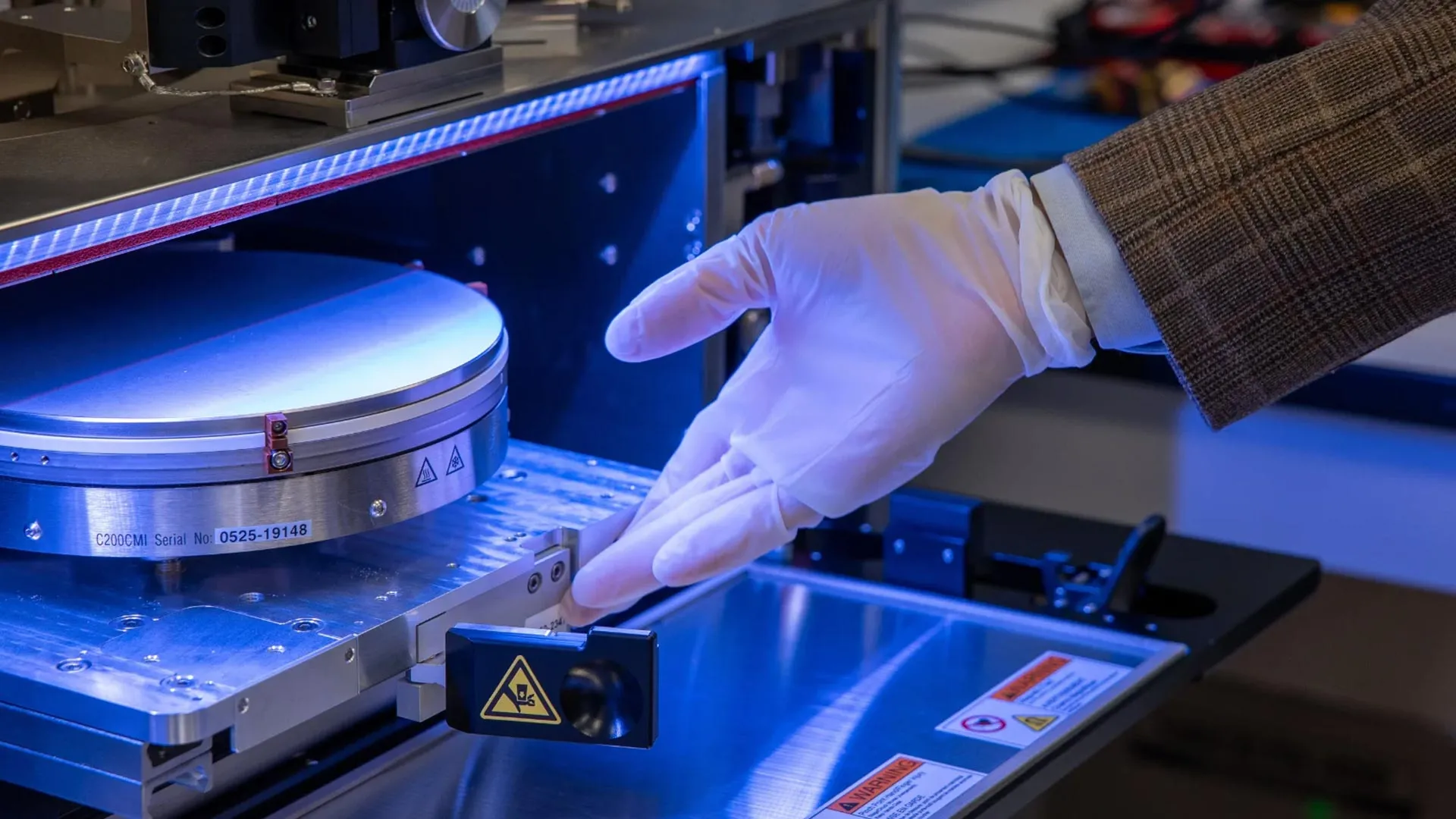

The current iteration of these microscopic robots represents just the genesis of a transformative technology. Future iterations hold the promise of enhanced programming capabilities, increased speed, the integration of additional sensors, and the ability to function in more challenging environments. The researchers have intentionally designed the system as a flexible platform, marrying a robust propulsion method with cost-effective electronics that can be readily adapted. "This is really just the first chapter," concludes Miskin. "We’ve shown that you can put a brain, a sensor, and a motor into something almost too small to see, and have it survive and work for months. Once you have that foundation, you can layer on all kinds of intelligence and functionality. It opens the door to a whole new future for robotics at the microscale." The foundational research was supported by grants from the National Science Foundation (NSF 2221576), the University of Pennsylvania Office of the President, the Air Force Office of Scientific Research (AFOSR FA9550-21-1-0313), the Army Research Office (ARO YIP W911NF-17-S-0002), the Packard Foundation, the Sloan Foundation, and the NSF National Nanotechnology Coordinated Infrastructure Program (NNCI-2025608), which supports the Singh Center for Nanotechnology, alongside contributions from Fujitsu Semiconductors. Key collaborators in this pioneering effort include Maya M. Lassiter, Kyle Skelil, Lucas C. Hanson, Scott Shrager, William H. Reinhardt, Tarunyaa Sivakumar, and Mark Yim from the University of Pennsylvania, and Dennis Sylvester, Li Xu, and Jungho Lee from the University of Michigan.