Kent Sorenson, Allonnia’s chief technology officer, articulates the strategic advantage of this approach: "The low-hanging fruit is to keep mining the mines that we have." This philosophy underscores the immense potential of leveraging existing infrastructure and resources. The global demand for critical metals like nickel, copper, and rare earth elements is experiencing an unprecedented surge, driven by the explosive growth of metal-intensive sectors. These include the burgeoning data center industry, the rapid proliferation of electric cars, and the widespread adoption of renewable energy projects. However, the extraction of these vital metals is becoming increasingly arduous and costly. This is largely because the most accessible and richest deposits have already been extensively exploited. Much like the ingenious method of rolling up the end of a toothpaste tube to retrieve the last remnants of paste, Allonnia’s innovative broth represents one of several emerging biotechnological solutions poised to help mining operations squeeze more valuable metals from aging mines, lower-grade ore bodies, and even vast piles of previously discarded waste.

The mining industry has a long-standing relationship with microbes, having intentionally seeded copper ore with them for decades. In current copper bioleaching sites, a common practice involves piling crushed copper ore into large heaps. Sulfuric acid is then added to create an environment conducive to the proliferation of specific acid-loving bacteria, such as Acidithiobacillus ferrooxidans. These microorganisms, in turn, produce a chemical compound that effectively breaks the molecular bonds between sulfur and copper, thereby liberating the metal for extraction. Historically, the extent to which miners could influence this microbial process was limited to maintaining the appropriate acidity levels and ensuring adequate aeration of the ore heaps.

However, the landscape of microbial mining is rapidly evolving. Elizabeth Dennett, CEO of the startup Endolith, highlights the transformative impact of decreasing costs in genetic tools. "The technology we’re using now didn’t exist a few years ago," she states, emphasizing the unprecedented ability to actively manage and optimize the microbial communities within these ore heaps. Endolith employs sophisticated DNA and RNA analysis techniques to meticulously characterize the microbial populations present in the copper-rich liquid that percolates through an ore heap. This detailed microbial profiling, when combined with a comprehensive suite of chemical analyses, provides invaluable insights. These insights enable Endolith to precisely identify and introduce specific microbial strains onto an ore heap, thereby optimizing the metal extraction process.

In rigorous laboratory tests conducted on ore samples from the mining giant BHP, Endolith’s proactive microbial management techniques demonstrated superior performance compared to traditional, passive bioleaching methods. This promising success has garnered significant attention, leading to a substantial funding round of $16.5 million. This capital infusion will facilitate Endolith’s transition from its Denver laboratory to pilot-scale deployments at active mine sites.

Despite these encouraging early achievements, seasoned experts like Corale Brierley, an engineer with extensive experience in metal bioleaching systems since the 1970s, raise pertinent questions regarding the scalability of these advanced microbial approaches. "What guarantees are you going to give the company that those organisms will actually grow?" Brierley asks, pointing to the inherent uncertainties of introducing engineered or specifically selected microbes into complex, natural environments.

Convincing established mining behemoths, who have meticulously optimized every facet of their operations, to adopt these novel biotechnologies will also present a formidable challenge. Diana Rasner, a mining technology analyst for the research firm Cleantech Group, observes, "They are acutely aware of what it takes to scale these technologies because they know the industry. They’ll be your biggest supporters, but they’re going to be your biggest critics." This sentiment underscores the high bar for evidence and proven reliability that large mining companies will demand.

Beyond the technical hurdles, venture-capital-backed biotechnology startups face the inherent pressure to deliver rapid returns on investment, a paradigm that often clashes with the lengthy testing and validation cycles characteristic of the mining industry. Rasner further elaborates, "This is not software," drawing a stark contrast between the agile development cycles of tech companies and the protracted timelines required for mining innovation. Mining companies typically require extensive, multi-year data sets before committing to the adoption of a new process.

A compelling example of this extended development cycle is Nuton, a subsidiary of the mining conglomerate Rio Tinto. Nuton has dedicated decades to refining a copper bioleaching process that utilizes a carefully curated blend of archaea and bacteria strains, augmented by specific chemical additives. However, the company only began demonstrating this technology publicly late last year, at a mine in Arizona. While Endolith and Nuton focus on utilizing naturally occurring or well-established microbial consortia, the startup 1849 is pursuing a more ambitious strategy, aiming for a significant performance leap through the genetic engineering of microbes.

CEO Jai Padmakumar of 1849 articulates this bold vision: "You can do what mining companies have traditionally done. Or you can try to take the moonshot bet and engineer them. If you get that, you have a huge win." Genetic engineering offers the potential to precisely tailor microbes to overcome specific extraction challenges unique to a customer’s ore body. However, this advanced approach also carries inherent risks. Buz Barstow, a Cornell University microbiologist specializing in biotechnology applications in mining, cautions that engineering organisms can paradoxically make them more difficult to cultivate and maintain in operational settings.

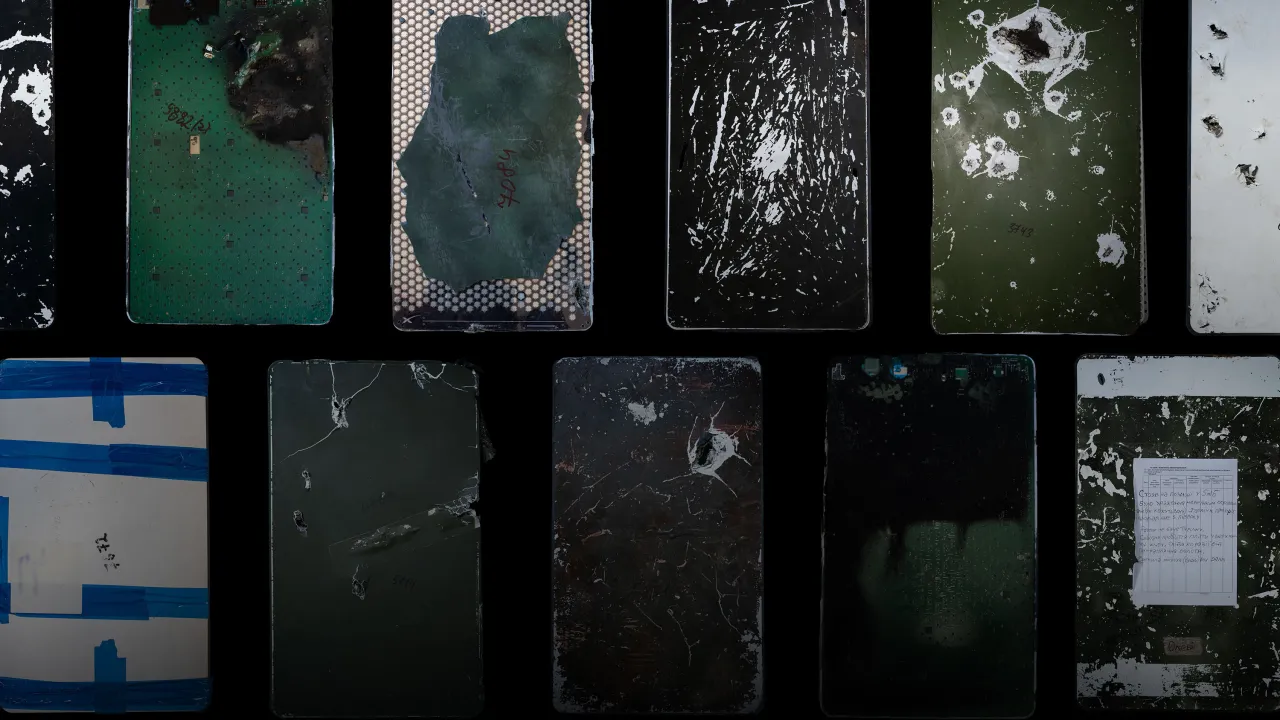

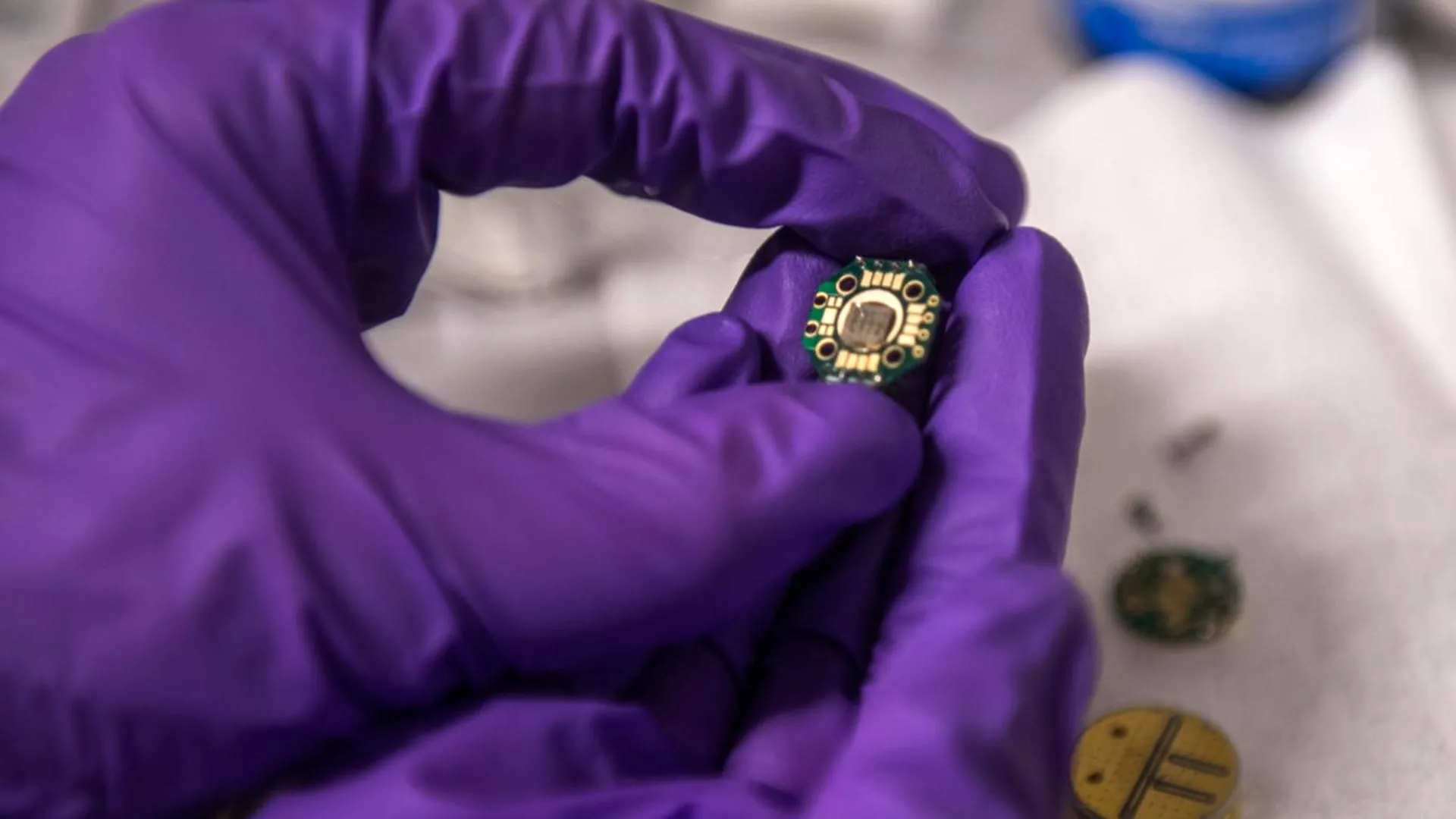

Other companies are strategically sidestepping the challenges associated with live organisms by focusing on the utilization of the products of microbial fermentation. Alta Resource Technologies, which recently secured $28 million in investment, is engineering microbes to produce proteins specifically designed for the extraction and separation of rare earth elements. Similarly, REEgen, a startup based in Ithaca, New York, leverages the organic acids generated by an engineered strain of Gluconobacter oxydans. These organic acids are then employed to extract rare earth elements not only from ore but also from a variety of waste materials, including metal recycling slag, coal ash, and discarded electronic components. "The microbes are the manufacturing," explains CEO Alexa Schmitz, a former student of Barstow’s lab, highlighting the role of microbes as biological factories.

For these nascent biotechnologies to make a substantial impact on the escalating global demand for metals, their scope must extend beyond copper and gold. Barstow emphasizes this crucial point, noting that in 2024, he initiated a project to map out genes that could be instrumental in extracting and separating a wider array of metals. Despite the formidable challenges that lie ahead, Barstow expresses optimism about the transformative potential of biotechnology in the mining sector, drawing a parallel to the seismic shift that hydraulic fracturing, or fracking, brought to the natural gas industry. "Biomining is one of these areas where the need… is big enough," he asserts, underscoring the vastness of the opportunity and the critical nature of the problem. The paramount challenge, however, will be the pace at which these innovations can be developed and deployed to keep apace with the ever-accelerating demand for these essential raw materials.