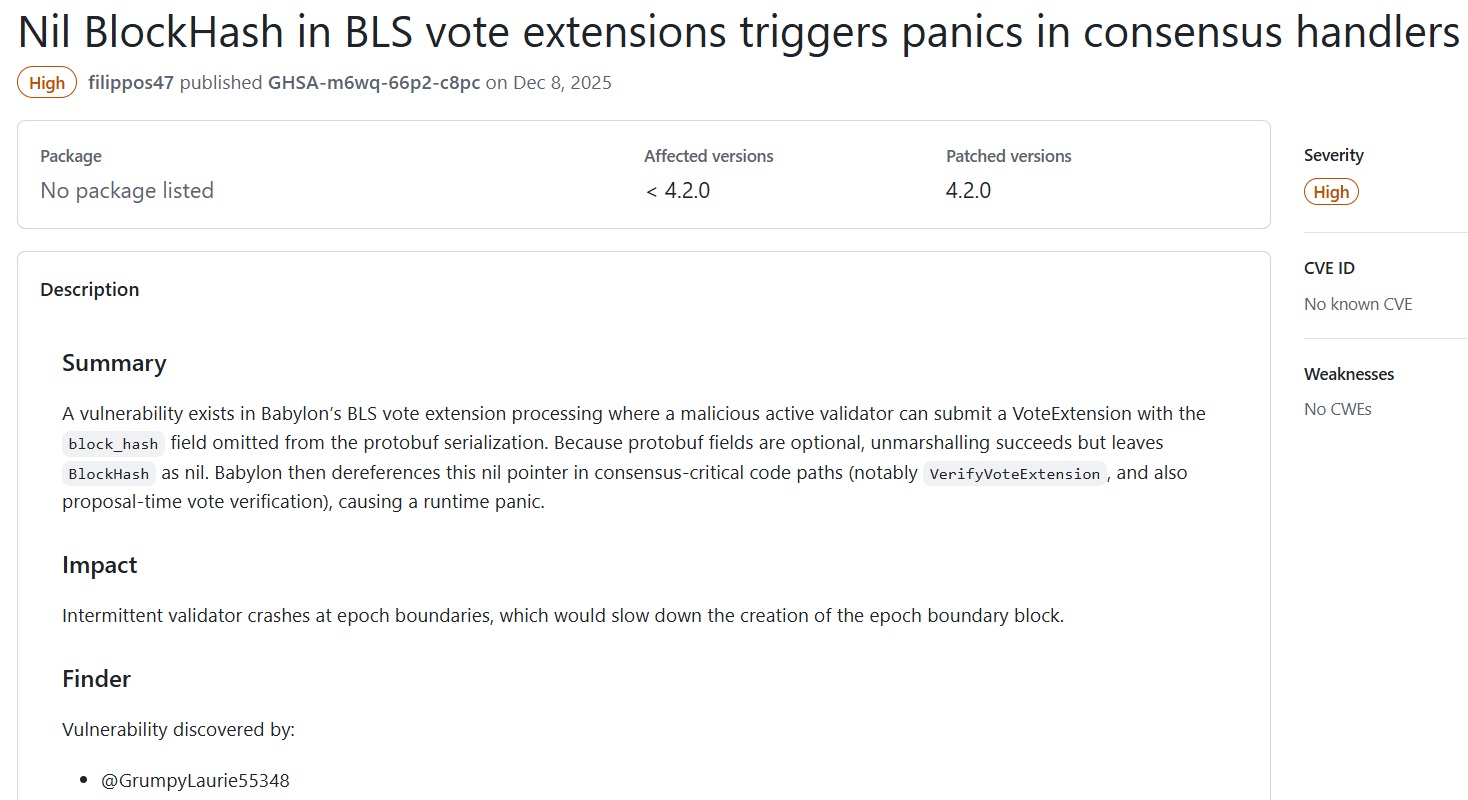

Historically, the widespread adoption of ec³ has been hampered by challenges related to low voltage and scalability. However, the latest research, published in the esteemed journal PNAS, details how the MIT team has managed to increase the energy storage capacity of ec³ by an order of magnitude. This substantial improvement means that a volume of concrete equivalent to a typical basement wall – approximately five cubic meters – could soon possess enough stored energy to meet the daily electricity demands of an average household. This leap forward represents a critical milestone in making ec³ a viable and practical energy solution.

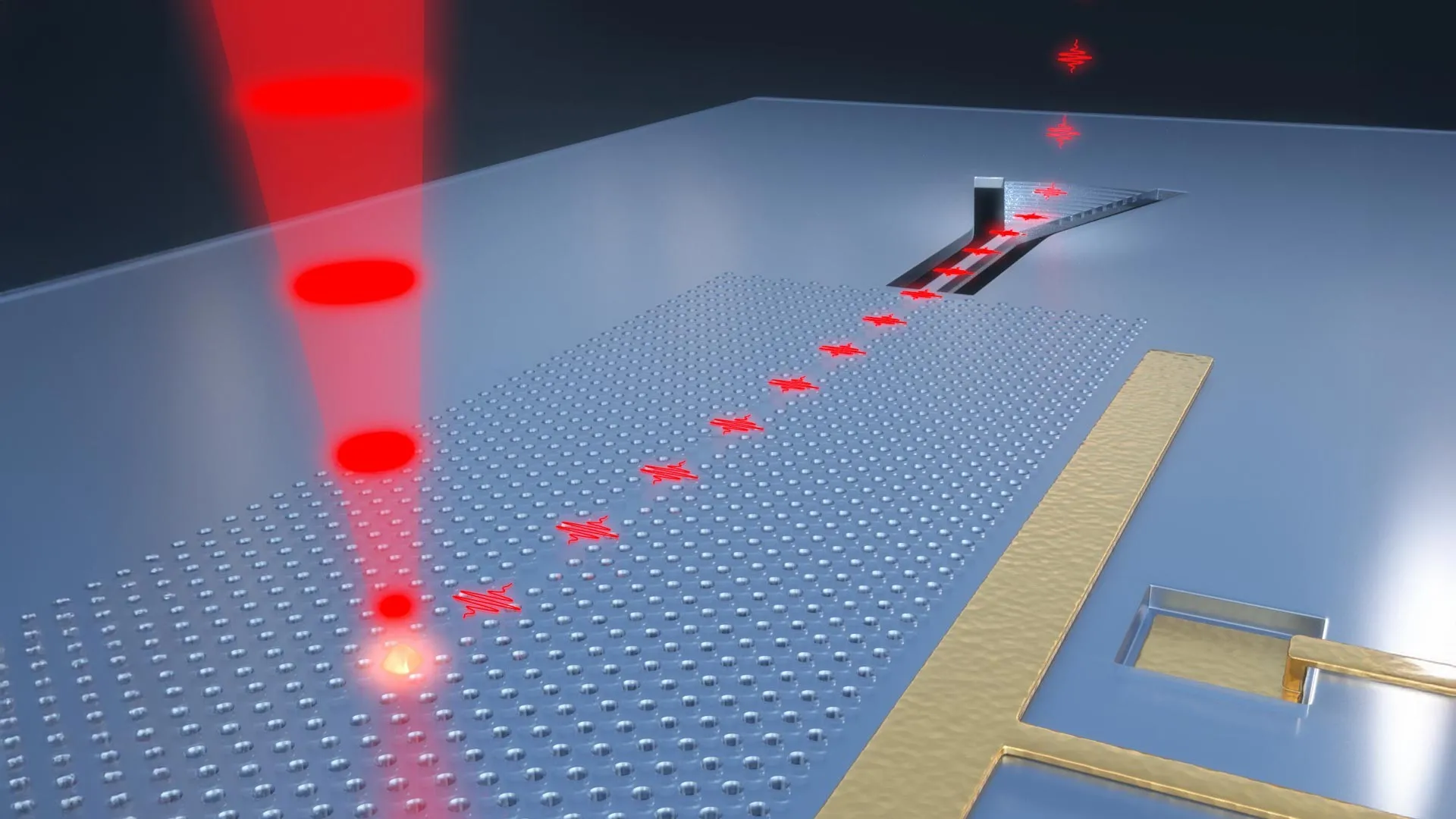

The breakthrough was achieved through a deep dive into the material’s fundamental workings. By employing high-resolution 3D imaging techniques, the researchers gained unprecedented insights into how the conductive carbon network, which essentially acts as the electrode, functions and interacts with electrolytes. This enhanced understanding allowed them to meticulously experiment with various electrolytes and their optimal concentrations. Damian Stefaniuk, a research scientist at the MIT Electron-Conducting Carbon-Cement-Based Materials Hub, which is spearheaded by associate professor Admir Masic, highlighted the extensive possibilities. "We found that there is a wide range of electrolytes that could be viable candidates for ec³," Stefaniuk stated. "This even includes seawater, which could make this a good material for use in coastal and marine applications, perhaps as support structures for offshore wind farms." The inclusion of seawater as a viable electrolyte is particularly significant, opening up eco-friendly and cost-effective applications in maritime environments, such as the foundational structures for offshore wind turbines, thereby addressing energy needs in remote and challenging locations.

Simultaneously, the team focused on optimizing the process of incorporating electrolytes into the concrete mix. By streamlining this step, they were able to cast thicker electrodes. Thicker electrodes are crucial for enhanced energy storage, as they provide a larger surface area for electrochemical reactions to occur, leading to a greater capacity to hold electrical charge. This dual approach – understanding the micro-level interactions and optimizing the macro-level fabrication – has been instrumental in achieving the remarkable increase in energy storage performance.

While ec³ may not yet match the energy density of conventional lithium-ion batteries, its unique advantages lie in its seamless integration into the very fabric of our built environment. Unlike standalone battery units, ec³ can be incorporated directly into structural components, meaning that a building’s walls, floors, or foundations could inherently serve as energy storage systems. Furthermore, the lifespan of ec³ is theoretically as long as the structure itself, offering a durable and permanent energy storage solution that eliminates the need for frequent battery replacements. This longevity and integrated nature address significant drawbacks associated with current battery technologies, such as disposal issues and maintenance requirements.

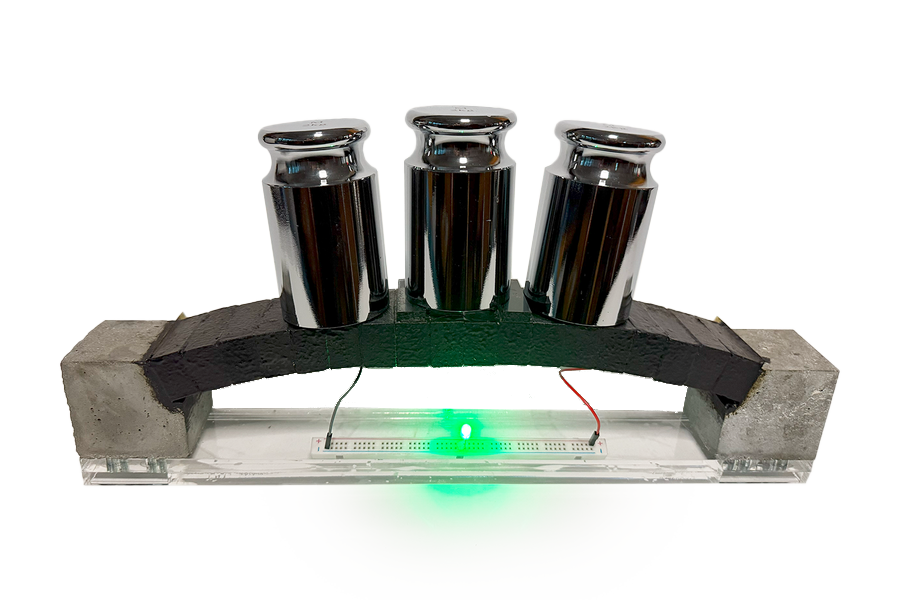

To vividly demonstrate the synergy between structural integrity and energy storage capabilities, the researchers constructed a miniature archway using ec³. This small-scale model not only proved its structural soundness by supporting its own weight and an additional load but also successfully powered an LED light. This tangible demonstration underscores the dual functionality of ec³, showcasing its potential to be both a load-bearing element and an active component in a distributed energy system. Imagine buildings that can store solar energy captured during the day and release it at night, or bridges that can power streetlights and sensors without relying on external grids.

The implications of this advancement are far-reaching. In urban environments, ec³ could revolutionize how we manage energy. Buildings could become self-sufficient energy hubs, reducing reliance on centralized power grids and mitigating the risk of widespread blackouts. The integration of energy storage directly into infrastructure could also facilitate the widespread adoption of renewable energy sources like solar and wind power, which are often intermittent. By storing excess energy generated during peak production times, ec³ would help to smooth out supply fluctuations, making renewables a more reliable and consistent energy source.

Beyond energy storage, the conductive nature of ec³ opens up possibilities for smart infrastructure. Embedded sensors could monitor structural health, traffic flow, or environmental conditions, transmitting data wirelessly powered by the very material they are integrated into. This could lead to more efficient urban planning, proactive maintenance of infrastructure, and enhanced safety. The ability for structures to communicate and self-power could usher in a new era of intelligent and responsive built environments.

The environmental benefits are also substantial. The production of cement is a significant contributor to global carbon emissions. While ec³ still utilizes cement, the prospect of reducing the need for separate battery manufacturing and disposal, which often involve hazardous materials and energy-intensive processes, presents a net positive environmental impact. The potential use of seawater as an electrolyte further enhances its eco-friendliness, particularly for coastal regions.

The journey from laboratory innovation to widespread commercial application is often long and complex. However, the progress made by the MIT team with ec³ is a significant leap forward. The increased energy storage capacity, coupled with the exploration of diverse and accessible electrolytes like seawater, addresses key limitations that previously held the technology back. The successful demonstration of a load-bearing, energy-storing arch provides compelling proof of concept, moving ec³ from theoretical possibility to practical demonstration.

Future research will likely focus on further optimizing the energy density, developing cost-effective manufacturing processes, and ensuring the long-term durability and safety of ec³ in various environmental conditions. Standardization of materials and construction techniques will also be crucial for its widespread adoption. The potential for ec³ to redefine the role of building materials, transforming them from passive structures into active participants in our energy ecosystem, is immense. As the world grapples with the urgent need for sustainable energy solutions and resilient infrastructure, innovations like electron-conducting carbon concrete offer a beacon of hope, paving the way for a more empowered and sustainable built future. The days of concrete simply being a foundation may soon be over, as it evolves into a dynamic and integral component of our energy landscape.