The once murky waters of the Buriganga River, a grim testament to the textile industry’s polluting legacy of dyes, chemicals, and heavy metals like lead and cadmium that flowed through Dhaka, are beginning to clear. This environmental blight was a stark reminder of the sector’s tragic past, epitomized by the devastating 2013 Rana Plaza factory collapse that claimed 1,134 lives and injured approximately 2,500. However, a quiet revolution is underway. Bangladesh, once synonymous with such calamities, is emerging as an unexpected vanguard of "frugal" factories, meticulously integrating resource-efficient technologies to drastically reduce waste, conserve precious water resources, and build robust resilience against the escalating impacts of climate change and the volatility of global supply chains. The nation now proudly hosts 268 LEED-certified garment factories, a number unparalleled by any other country. Dye plants are actively transitioning to safer chemical alternatives, tanneries are embracing cleaner tanning methods and implementing sophisticated wastewater treatment systems, and workshops are making the switch to energy-efficient LED lighting, with solar panels increasingly adorning factory rooftops. Across the hundreds of facilities lining the Buriganga and other industrial hubs in Bangladesh, a new narrative is being stitched, one woven from the vibrant threads of environmental responsibility and sustainable production.

At the forefront of this transformation is Fakir Eco Knitwears, a LEED Gold-certified factory situated in Narayanganj, a bustling city near Dhaka. Here, innovative design choices, such as the strategic integration of skylights, have led to a remarkable 40% reduction in energy consumption for artificial lighting. Complementing this, AI-driven fabric cutters empower workers to meticulously recycle an impressive 95% of fabric scraps into new yarns, minimizing waste at its source. Md. Anisuzzaman, an engineer at Fakir Eco Knitwears, elaborates on their eco-conscious approach: "We save energy by utilizing daylight, solar power, and rainwater instead of relying heavily on air conditioning and boilers. This demonstrates how local resources can be leveraged to make production both greener and more sustainable." This forward-thinking factory exemplifies a holistic approach to environmental stewardship, where every element of the production process is scrutinized for its ecological footprint.

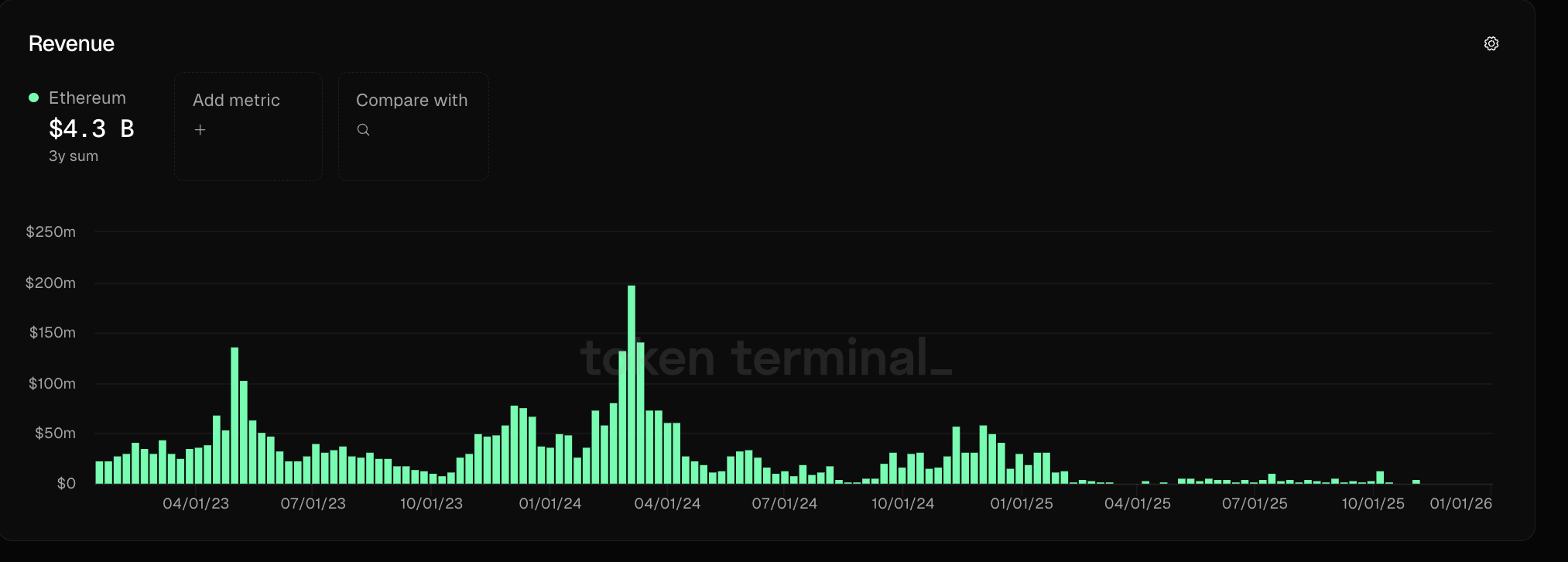

The significant shift towards green factories in Bangladesh is a multifaceted endeavor, propelled by a strategic combination of substantial factory investments, accessible loans from Bangladesh Bank’s Green Transformation Fund, and the growing influence of international buyers. These buyers are increasingly rewarding compliance with sustainable practices through continued, and often expanded, orders. A pivotal initiative driving this change is the Partnership for Cleaner Textile (PaCT) program, spearheaded by the World Bank Group’s International Finance Corporation. Launched in 2013, PaCT has been instrumental in guiding over 450 factories towards adopting cleaner production methodologies. The program’s impact is quantifiable: it is currently saving an astounding 35 billion liters of fresh water annually, a volume sufficient to meet the basic needs of 1.9 million people, highlighting the immense potential for large-scale water conservation within the industry.

The visual evidence of this green revolution is striking. Solar panels now glint from the rooftops of factories, harnessing clean energy to reduce their reliance on fossil fuels. Advanced technologies like exhaust gas absorption chillers are deployed to efficiently manage heat, maintaining comfortable working temperatures on factory floors at around 28°C (82°F) while minimizing energy expenditure. Furthermore, a closed-loop water management system is becoming increasingly common, with water reclaimed at the factory’s sewage treatment plant being repurposed for use in restrooms, showcasing a commitment to water conservation at every level. These tangible advancements are not merely symbolic; they represent a fundamental re-evaluation of industrial practices, moving away from the polluting norms of the past towards a more responsible and sustainable future.

While these advancements in environmental sustainability are commendable and represent a significant step forward, it is crucial to acknowledge that Bangladesh’s formidable $40 billion garment industry still has a considerable journey ahead. The positive environmental transformations at the factory level have, unfortunately, not yet translated into commensurate improvements in the working and living conditions of the sector’s 4.4 million dedicated workers. Issues such as wage theft and persistent delays in payment remain widespread concerns, casting a shadow over the otherwise positive narrative of industrial progress. The current minimum wage, set at approximately 12,500 taka per month (around $113), falls significantly short of the $200 proposed by labor unions, a disparity that frequently fuels strikes and protests concerning fair wages, overtime compensation, and job security.

A.K.M. Ashraf Uddin, executive director of the Bangladesh Labour Foundation, a non-profit organization advocating for labor rights, offers a sobering perspective: "Since Rana Plaza, building safety and factory conditions have improved, but the underlying mindset remains largely unchanged. Profit still takes precedence, and workers’ freedom of speech has yet to be fully realized." This sentiment underscores a critical challenge: achieving true sustainability requires not only environmental responsibility but also social equity and fair treatment for all individuals involved in the production process. The focus on green initiatives, while essential, must be balanced with a robust commitment to worker welfare and human rights.

The potential for exacerbating existing inequalities is a genuine concern. The garment sector is characterized by a large number of smaller factories, many of which face significant financial hurdles in affording the necessary investments for green upgrades. Without these crucial improvements, these businesses risk being excluded from key international markets, particularly those with stringent environmental and ethical sourcing requirements. The European Union, for instance, is set to implement new regulations in 2027 mandating companies to address human rights and environmental challenges throughout their supply chains. This impending legislation highlights the interconnectedness of environmental and social sustainability with market access. Therefore, while a cleaner Buriganga River represents a significant ecological victory, it addresses only a fraction of the broader spectrum of needs that continue to challenge the industry and its workforce. The path forward requires a comprehensive approach that prioritizes both environmental stewardship and the fundamental rights and well-being of every worker, ensuring that Bangladesh’s garment industry truly weaves a future that is both sustainable and equitable for all.