However, a groundbreaking development from researchers at the NYU Tandon School of Engineering promises to dissolve this bottleneck, offering a path forward that embraces both innovation and environmental stewardship. In a seminal paper published in the prestigious journal ACS Applied Materials & Interfaces, these pioneering scientists unveil a revolutionary solution: the creation of an "ink" formulated from environmentally benign quantum dots designed to detect infrared light without resorting to mercury, lead, or other heavily regulated heavy metals. This breakthrough not only addresses the immediate environmental concerns but also fundamentally reimagines the manufacturing process for IR detectors, moving away from laborious, expensive, and time-consuming traditional methods.

Historically, the fabrication of IR detectors has been an intricate and painstakingly slow process. Imagine assembling a microscopic puzzle, where each atom is meticulously placed, one by one, across the vast array of pixels that form a detector. This atom-by-atom assembly, akin to working under a powerful microscope, is not only incredibly labor-intensive but also prohibitively expensive and inherently limits the scalability of production. The NYU Tandon team’s innovative approach sidesteps this antique methodology entirely. Their quantum dots, known as colloidal quantum dots, are synthesized in a liquid solution, a process more akin to brewing ink than to traditional semiconductor manufacturing. This "ink" can then be applied using scalable coating techniques, mirroring the efficient, high-volume processes already employed in industries like packaging and newspaper printing. This paradigm shift from painstaking manual assembly to fluid-based processing promises to dramatically slash manufacturing costs and, crucially, unlock the door to widespread commercial adoption across a multitude of applications.

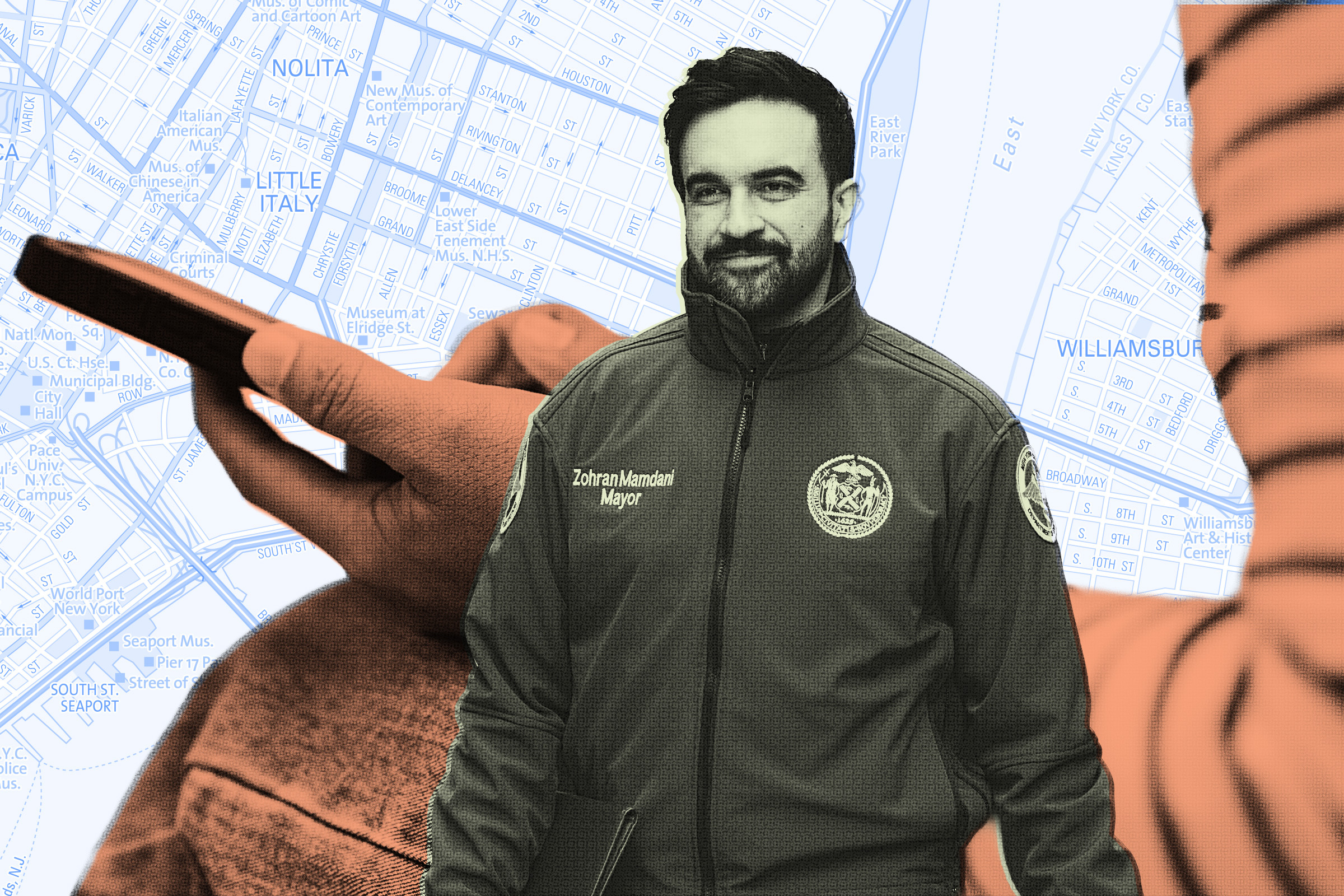

The confluence of tightening environmental regulations and the explosive growth in demand for infrared imaging has created what Ayaskanta Sahu, an associate professor in the Department of Chemical and Biomolecular Engineering (CBE) at NYU Tandon and the study’s senior author, describes as a "perfect storm." This scenario, he elaborates, presents significant hurdles for companies striving to scale up the production of thermal imaging systems, effectively creating bottlenecks that stifle progress. The environmental compliance mandate, driven by growing global awareness and stricter legislation, is making the use of traditional, high-performance materials increasingly untenable. Simultaneously, the accelerating development of autonomous driving, advanced medical imaging for early disease detection, and sophisticated surveillance and defense systems is fueling an insatiable appetite for more capable and ubiquitous IR technology. The traditional approach, relying on materials like mercury cadmium telluride (MCT) or indium antimonide (InSb), is now under immense pressure due to their heavy metal content and the associated disposal and manufacturing challenges.

Beyond the environmental and manufacturing hurdles, the NYU Tandon researchers also tackled a critical technical challenge: ensuring their quantum dot ink possessed sufficient electrical conductivity to effectively relay the subtle signals generated by incoming infrared light. Their ingenious solution lies in a sophisticated technique called solution-phase ligand exchange. This process allows for the precise tailoring of the quantum dot’s surface chemistry, an engineering feat that significantly enhances their performance within electronic devices. What makes this particularly remarkable is that, unlike traditional fabrication methods which often result in uneven, cracked films, this solution-based approach yields remarkably smooth and uniform coatings in a single, streamlined step. This uniformity is paramount for scalable manufacturing, ensuring consistent performance across large arrays of detectors.

The performance metrics of the resulting quantum dot-based IR detectors are nothing short of impressive. These novel devices demonstrate an astonishing responsiveness to infrared light, reacting on the microsecond timescale. To put this into perspective, the human eye’s blink reflex is hundreds of times slower, highlighting the speed and sensitivity of this new technology. Furthermore, they possess the remarkable ability to detect signals as faint as a nanowatt of light, a level of sensitivity crucial for applications requiring the detection of minute thermal variations or distant objects.

The excitement surrounding this development is palpable. Graduate researcher Shlok J. Paul, the lead author of the study, expresses his enthusiasm, stating, "What excites me is that we can take a material long considered too difficult for real devices and engineer it to be more competitive." He further elaborates on the future potential, envisioning that with continued research and development, these quantum dot materials could be engineered to operate even deeper within the infrared spectrum, a spectral region where currently, there are very few suitable materials available for detection tasks. This opens up possibilities for entirely new classes of applications currently beyond our technological reach.

This current work builds upon a foundation of prior research from the same lead researchers, who had previously developed innovative transparent electrodes utilizing silver nanowires. These electrodes possess the unique ability to remain highly transparent to infrared light while simultaneously demonstrating exceptional efficiency in collecting electrical signals. This earlier breakthrough addressed a crucial component of the overall IR camera system, namely the signal extraction mechanism.

When combined with the newly developed quantum dot ink, these advancements represent a comprehensive solution addressing the two primary components of modern infrared imaging systems. The quantum dots provide the environmentally compliant sensing capability, effectively "seeing" the infrared light. Concurrently, the transparent electrodes, a product of their prior research, handle the vital tasks of signal collection and processing, ensuring that the information captured by the quantum dots is efficiently and accurately relayed. This synergistic combination is particularly impactful for the development of large-area infrared imaging arrays. These arrays are essential for applications requiring broad field-of-view detection and the simultaneous readout of signals from millions of individual detector pixels. The transparent electrodes are instrumental in this context, allowing incident infrared light to freely reach the quantum dot detectors while simultaneously providing the necessary electrical pathways for signal extraction.

The implications for accessibility and cost-effectiveness are profound. "Every infrared camera in a Tesla or smartphone needs detectors that meet environmental standards while remaining cost-effective," remarks Sahu. He envisions that their innovative approach has the potential to significantly democratize these technologies, making them far more affordable and thus accessible to a wider range of manufacturers and consumers. The integration of such detectors into everyday devices like smartphones could revolutionize how we interact with our environment, enabling new features and functionalities.

While the performance of these new quantum dot detectors, in certain specific measurements, may still fall slightly short of the very best heavy-metal-based detectors currently available, the researchers are optimistic. They anticipate that ongoing advancements in quantum dot synthesis techniques and further refinements in device engineering will rapidly close this performance gap. The inherent advantages in terms of environmental safety, cost-effectiveness, and manufacturing scalability provide a strong impetus for continued investment and development in this promising technology.

The groundbreaking research was conducted by a dedicated team at NYU Tandon CBE, including Ayaskanta Sahu, Shlok J. Paul, Letian Li, Zheng Li, Thomas Kywe, and Ana Vataj. The critical support for this pioneering work was provided by the Office of Naval Research and the Defense Advanced Research Projects Agency (DARPA), underscoring the national importance and strategic value of this advancement in IR technology. This collaboration highlights the commitment to developing cutting-edge, environmentally responsible solutions for critical defense and civilian applications.