The global energy landscape is undergoing a profound transformation, driven by escalating electricity demands fueled by a warming planet, burgeoning economies, and the insatiable power requirements of emerging technologies like artificial intelligence. As nations grapple with the dual imperatives of climate change mitigation and energy security, nuclear power is experiencing a resurgence of interest. However, the conventional nuclear reactor model, largely unchanged since the mid-20th century, presents significant hurdles in terms of cost, construction time, and public perception. Enter the next generation of nuclear reactor designs, poised to revolutionize the industry by shedding the monolithic, bespoke approach of their predecessors and embracing innovation in size, fuel, and cooling systems. These advancements aim to deliver nuclear power that is not only carbon-free but also safer, more reliable, more affordable, and quicker to deploy, offering a vital tool in the fight against greenhouse gas emissions.

The cornerstone of this nuclear renaissance lies in the concept of Small Modular Reactors (SMRs). Unlike the colossal, site-specific behemoths of the past, SMRs are designed for mass production on an assembly line, promising significant cost reductions through standardization and economies of scale. Their smaller footprint opens up a world of new applications, from powering remote communities and industrial facilities to providing energy independence for military bases. China’s Linglong One, the world’s first land-based commercial SMR, is slated to come online in 2026, marking a significant milestone. In the United States, Kairos Power’s Hermes 2 demonstration reactor is expected to be operational by 2030, further signaling the growing momentum behind SMR development. While the promise of cost savings is substantial, challenges remain, as site-specific environmental conditions like seismic activity or flood risks will still necessitate some degree of customization, potentially impacting the envisioned assembly-line efficiency.

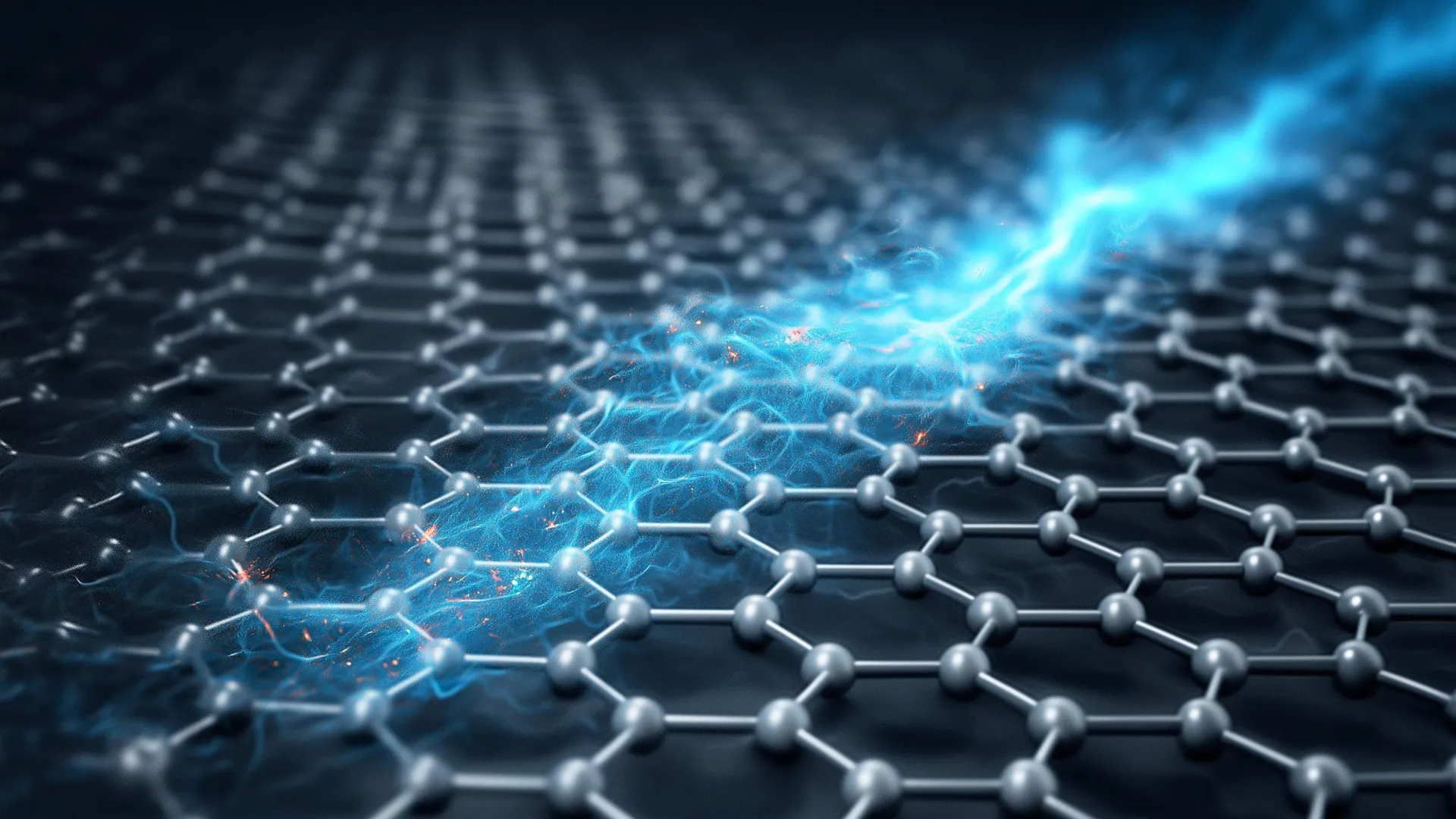

Beyond the physical size, innovation is also transforming the very fuel that powers these reactors. Traditional nuclear reactors rely on uranium enriched to between 3% and 5% of the fissile U-235 isotope. Next-generation reactors are exploring the use of High-Assay Low-Enriched Uranium (HALEU), which boasts a U-235 concentration ranging from 5% to 20%. This higher enrichment allows for longer operational cycles between refueling and enables the adoption of advanced fuel forms like Tri-Structural Isotropic (TRISO) fuel. TRISO particles, each less than a millimeter in diameter, encapsulate uranium kernels within multiple layers of carbon and ceramic. These robust coatings act as an intrinsic containment system, rendering them highly resistant to neutron irradiation, corrosion, oxidation, and extreme temperatures exceeding 1,800 degrees Celsius. Embedded in graphite pellets, TRISO fuel offers enhanced safety features, ensuring that fission products remain securely contained even under demanding operational conditions.

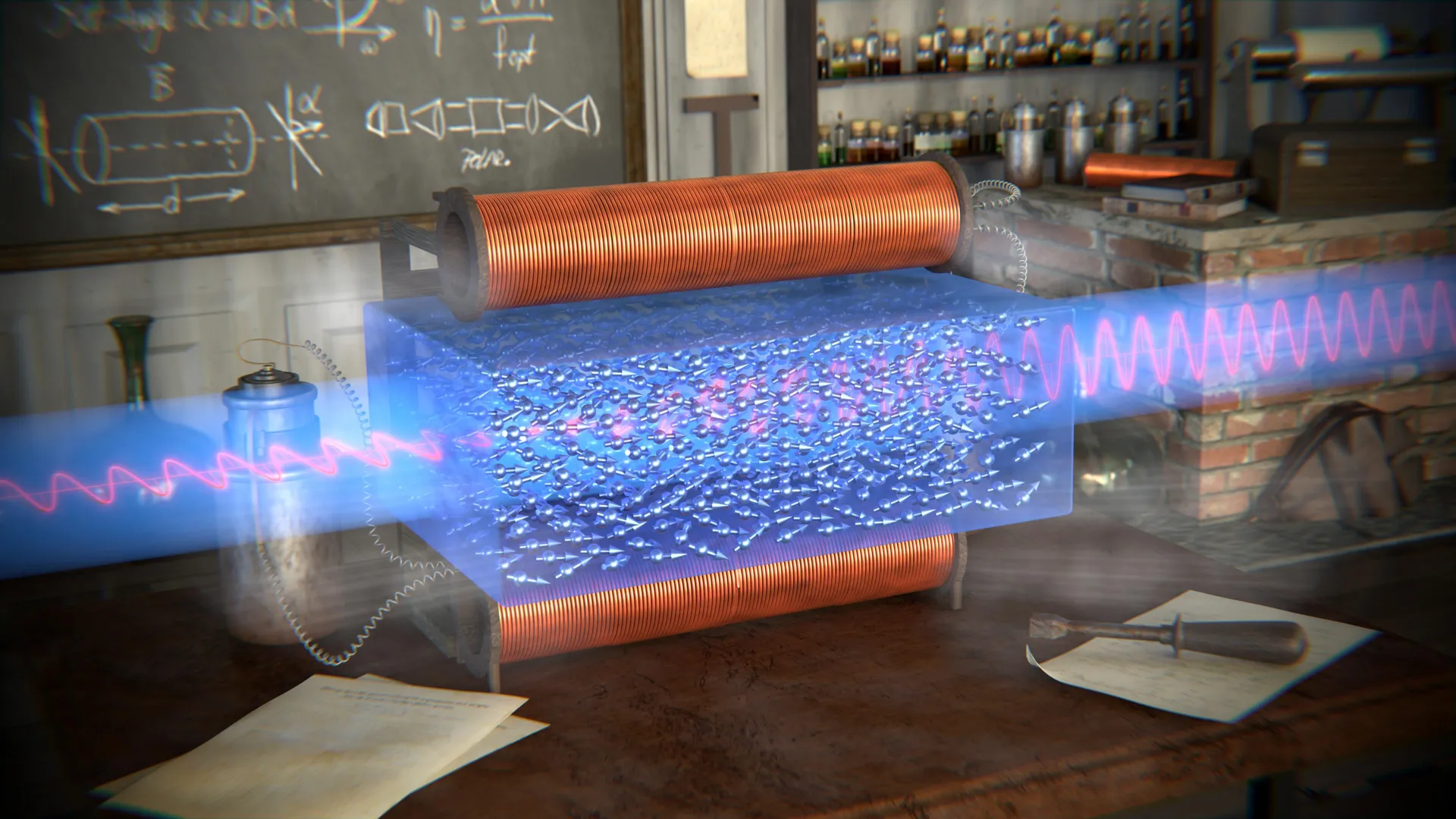

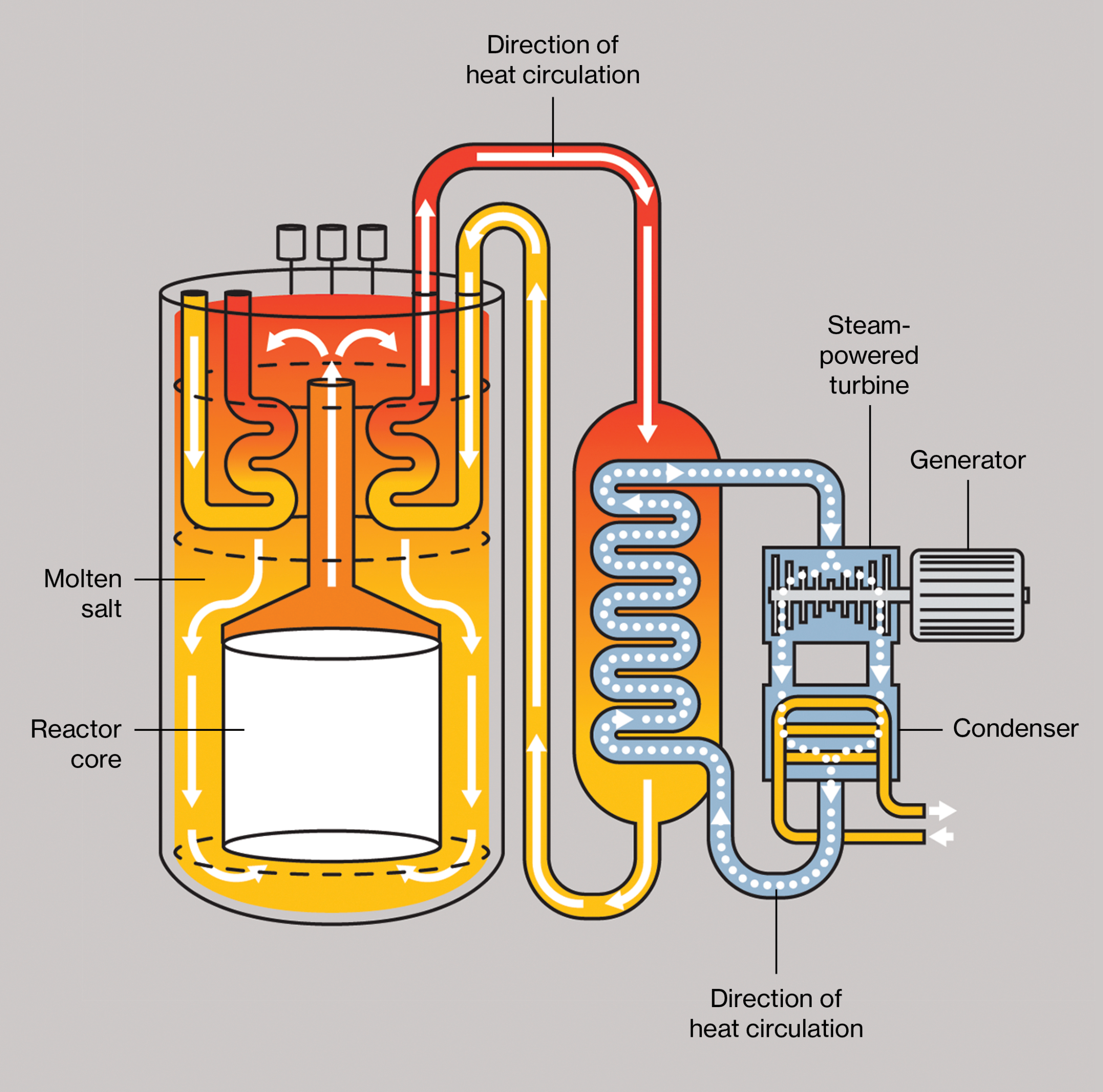

The method of heat transfer within a reactor, known as the coolant system, is another area ripe for reinvention. While most current reactors utilize pressurized water, new designs are venturing into gaseous coolants, liquid metals, and molten salts. These alternative coolants operate at significantly higher temperatures – upwards of 500 degrees Celsius compared to water’s maximum of around 300 degrees Celsius. This elevated operating temperature translates to more efficient steam production and improved overall energy conversion. Crucially, these advanced coolants often operate at much lower pressures than high-pressure water systems, closer to atmospheric pressure. This reduction in pressure significantly simplifies containment requirements, negating the need for the heavily reinforced, high-pressure vessels characteristic of conventional reactors, thereby enhancing safety and reducing construction complexity.

However, these novel coolant systems are not without their own set of challenges. Molten salts, for instance, can be corrosive in the presence of oxygen, necessitating careful selection of construction materials. Liquid metal coolants, such as sodium, pose a risk of explosion upon contact with water, demanding stringent containment protocols. Despite these complexities, the potential benefits of these alternative coolants in terms of safety and efficiency are driving continued research and development. Ultimately, the success of these next-generation nuclear reactors hinges on their ability to demonstrate not only their power-generating capabilities but also their long-term safety, reliability, and economic viability, proving they are a robust and sustainable solution for the world’s growing energy needs.