In a groundbreaking development poised to revolutionize night vision technology and expand the reach of infrared imaging, researchers at NYU Tandon School of Engineering have successfully engineered an environmentally friendly "quantum ink" capable of detecting infrared light without relying on toxic heavy metals. This innovation directly addresses a critical bottleneck for manufacturers of infrared cameras, who are increasingly constrained by stringent environmental regulations that ban the use of materials like mercury and lead. The urgency for such a solution is amplified by the surging demand for infrared detectors across diverse civilian applications, including autonomous vehicles, advanced medical imaging, and enhanced national security, all of which are currently hampered by the performance versus compliance dilemma.

The development, detailed in a recent paper published in the prestigious journal ACS Applied Materials & Interfaces, represents a significant departure from the complex and costly traditional methods of fabricating infrared detectors. Historically, these detectors have been built through painstakingly slow, atom-by-atom assembly processes, akin to piecing together an intricate puzzle under a microscope. This meticulous approach, while yielding high performance, is inherently expensive and time-consuming, making widespread adoption challenging.

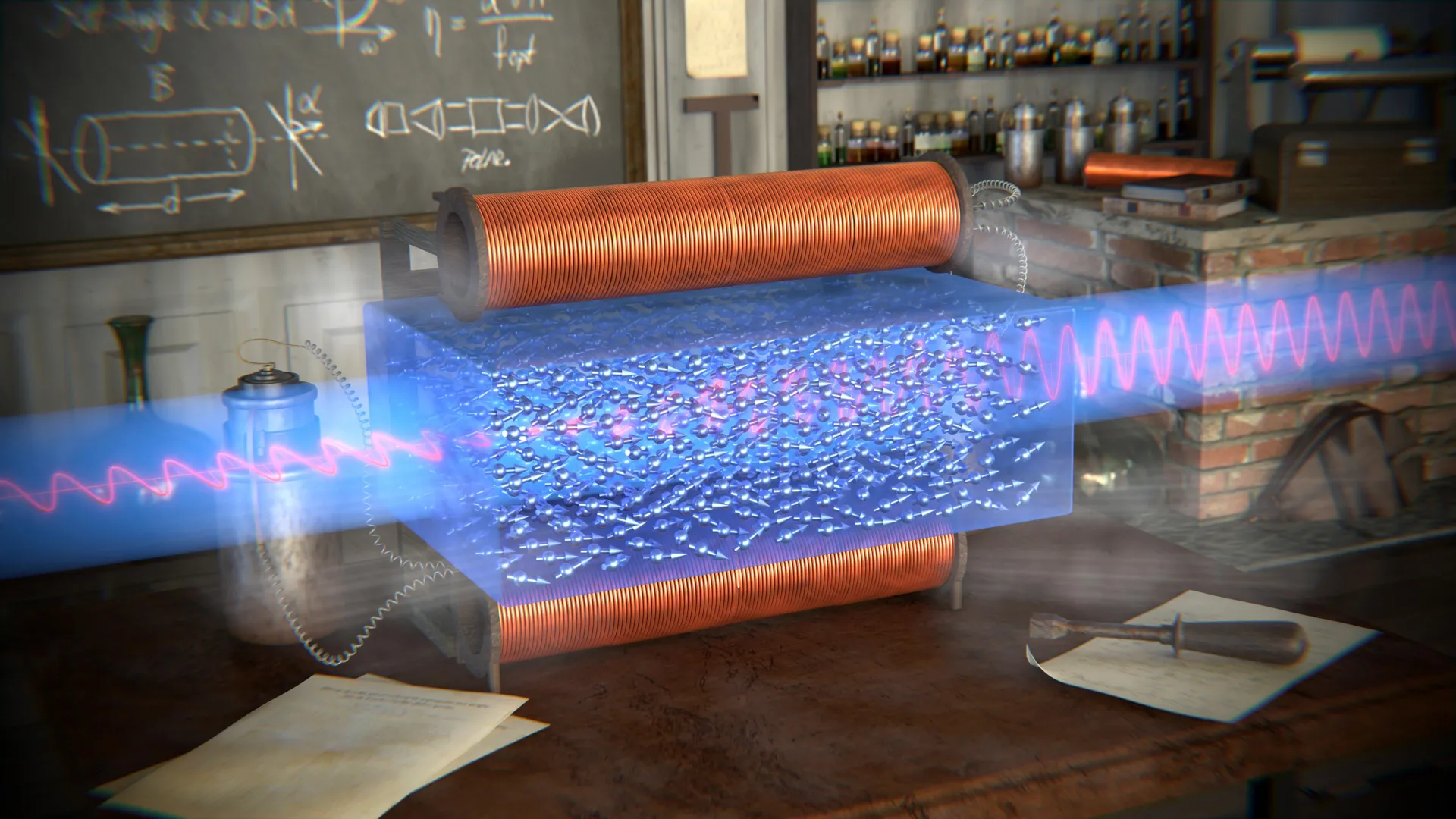

The NYU Tandon team’s innovation lies in their use of colloidal quantum dots, which are synthesized and processed entirely in a liquid solution. This "brewing" process is far more akin to creating an ink, allowing for deposition using scalable coating techniques. These techniques are remarkably similar to those employed in high-volume manufacturing processes like those used for packaging or printing newspapers – a stark contrast to the microscopic, piece-by-piece assembly of traditional methods. This fundamental shift from painstaking manual assembly to a solution-based, scalable manufacturing approach promises to dramatically reduce production costs and unlock the door for broader commercial applications of infrared technology.

Ayaskanta Sahu, an associate professor in the Department of Chemical and Biomolecular Engineering (CBE) at NYU Tandon and the senior author of the study, articulated the critical juncture at which the industry finds itself. "The industry is facing a perfect storm where environmental regulations are tightening just as demand for infrared imaging is exploding," he stated. "This creates real bottlenecks for companies trying to scale up production of thermal imaging systems." The quantum ink offers a compelling pathway to circumvent these bottlenecks, providing a compliant and potentially more affordable alternative.

Beyond the environmental and manufacturing cost advantages, the researchers also tackled a significant technical hurdle: ensuring the quantum dot ink possessed sufficient electrical conductivity to effectively relay signals from incoming infrared light. They achieved this through an ingenious technique known as solution-phase ligand exchange. This process allows for the precise tailoring of the quantum dot surface chemistry, thereby enhancing their performance within electronic devices. Crucially, this solution-based method, unlike traditional fabrication techniques that often result in uneven or cracked films, yields remarkably smooth and uniform coatings in a single, streamlined step. This uniformity is paramount for achieving consistent performance and enabling scalable manufacturing.

The resulting infrared detectors exhibit impressive performance characteristics. They demonstrate a rapid response time to infrared light, operating on the microsecond timescale. To put this into perspective, the human eye blinks at speeds hundreds of times slower, highlighting the extreme sensitivity and speed of these new detectors. Furthermore, they are capable of detecting signals as faint as a nanowatt of light, indicating a high degree of sensitivity for capturing subtle infrared signatures.

Shlok J. Paul, a graduate researcher and the lead author of the study, expressed his enthusiasm for the potential of this material. "What excites me is that we can take a material long considered too difficult for real devices and engineer it to be more competitive," he remarked. "With more time this material has the potential to shine deeper in the infrared spectrum where few materials exist for such tasks." This forward-looking statement suggests that the quantum ink technology has the capacity to extend into even more challenging and previously inaccessible regions of the infrared spectrum.

This latest work builds upon earlier foundational research conducted by the same lead researchers. Previously, they developed novel transparent electrodes utilizing silver nanowires. These electrodes are crucial components in infrared camera systems, as they must remain highly transparent to infrared light while simultaneously efficiently collecting electrical signals generated by the detectors. The combination of these newly developed quantum dot detectors and the previously engineered transparent electrodes represents a comprehensive solution, addressing both the sensing and signal processing aspects of infrared imaging systems.

The synergy between the environmentally compliant quantum dot sensors and the efficient signal-collecting transparent electrodes is particularly significant for the development of large-area infrared imaging arrays. These arrays, essential for applications requiring broad field-of-view coverage, necessitate high-performance detection across vast areas and the efficient readout of signals from millions of individual detector pixels. The transparent electrodes, by allowing unimpeded light penetration to the quantum dots and providing robust electrical pathways for signal extraction, are instrumental in realizing these complex imaging systems.

The implications of this research extend directly to the mass-market adoption of infrared technology. "Every infrared camera in a Tesla or smartphone needs detectors that meet environmental standards while remaining cost-effective," Professor Sahu emphasized. "Our approach could help make these technologies much more accessible." This suggests that the quantum ink could pave the way for more affordable and widely available infrared capabilities in consumer electronics, automotive safety systems, and other burgeoning fields.

While the performance of the current quantum dot detectors, in certain measurements, still falls short of the most advanced heavy-metal-based detectors, the researchers are optimistic about future improvements. They anticipate that continued advancements in quantum dot synthesis techniques and ongoing refinements in device engineering will steadily narrow this performance gap. The inherent advantages in terms of environmental compliance and manufacturing scalability provide a strong impetus for further research and development.

The research team behind this breakthrough includes not only Professor Sahu and Shlok J. Paul but also fellow NYU Tandon CBE researchers Letian Li, Zheng Li, Thomas Kywe, and Ana Vataj. The project received crucial support from esteemed organizations such as the Office of Naval Research and the Defense Advanced Research Projects Agency, underscoring the strategic importance and potential impact of this innovation for national security and technological advancement. The successful "brewing" of this quantum ink signifies a pivotal step towards a future where advanced infrared imaging is not only more powerful and versatile but also environmentally responsible and economically accessible.