A groundbreaking study, recently published in the esteemed journal Light: Science & Applications, heralds a significant leap forward in this critical area. A collaborative effort involving researchers from Humboldt-Universität zu Berlin, the Leibniz Institute of Photonic Technology, and the University of Stuttgart has unveiled a novel quantum memory architecture. This innovative design utilizes meticulously 3D-nanoprinted structures, aptly termed "light cages," which are subsequently filled with atomic vapor. By ingeniously integrating both light and atoms onto a single chip, the research team has engineered a versatile platform specifically designed for enhanced scalability and effortless integration into existing quantum photonic systems, promising to revolutionize quantum communication and computation.

The Distinctive Edge of Light Cages

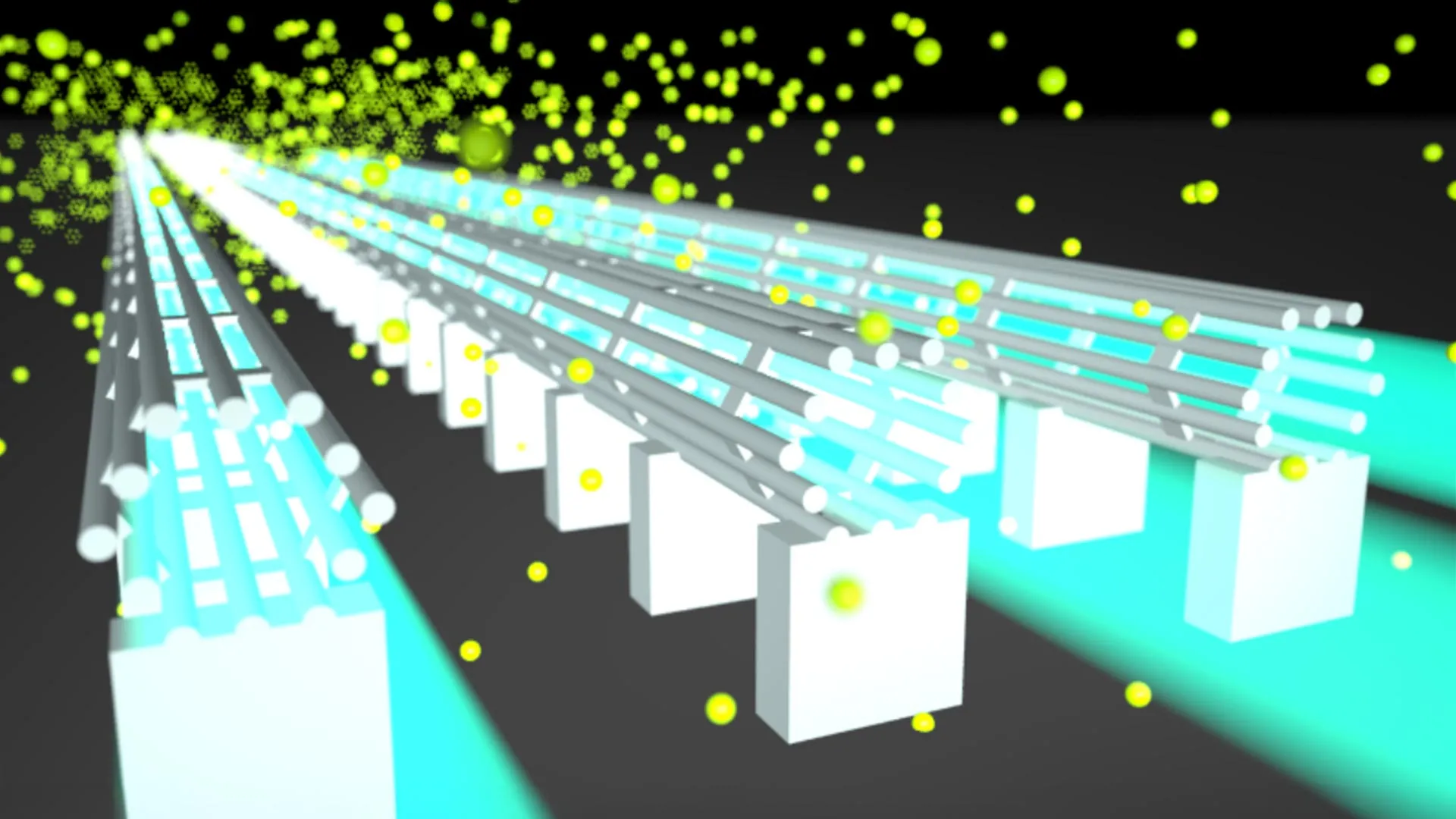

The ingenuity of light cages lies in their unique structural design. These are not ordinary waveguides; they are hollow-core structures meticulously engineered to confine and guide light with exceptional precision, while simultaneously providing unhindered access to the internal space. This characteristic grants them a profound advantage over conventional hollow-core fibers, which are notoriously time-consuming to fill with atomic vapor, often requiring months for the process. In stark contrast, the inherently open architecture of light cages facilitates a dramatically accelerated diffusion of cesium atoms into the core, reducing the filling time to a mere matter of days without any discernible compromise in optical performance.

The fabrication of these intricate structures is achieved through the advanced technique of two-photon polymerization lithography, leveraging commercially available 3D printing systems. This cutting-edge approach empowers researchers to directly print complex hollow-core waveguides onto silicon chips with an astonishing degree of precision. To safeguard these delicate devices from potential chemical reactions with cesium, the internal surfaces of the waveguides are treated with a specialized protective coating. Rigorous testing has demonstrated the remarkable durability of this coating, showing no signs of degradation even after an extensive five-year operational period, a testament to the system’s exceptional long-term stability and robustness.

The research team articulated the significance of their creation, stating, "We created a guiding structure that allows quick diffusion of gases and fluids inside its core, with the versatility and reproducibility provided by the 3D-nanoprinting process. This enables true scalability of this platform, not only for intra-chip fabrication of the waveguides but also inter-chip, for producing multiple chips with the same performance." This quote underscores the dual benefit of rapid atomic filling and the inherent precision and replicability of 3D nanoprinting, paving the way for mass production of identical quantum memory components.

Transforming Light into Stored Quantum Information

Within the confines of these meticulously crafted light cages, incoming light pulses are efficiently transformed into collective excitations of the surrounding atomic ensemble. Following a precisely chosen storage duration, a control laser is employed to meticulously reverse this process, releasing the stored light precisely at the desired moment. In a pivotal experimental demonstration, the researchers successfully achieved the storage of extremely faint light pulses, each containing merely a handful of photons, for durations extending to several hundred nanoseconds. The team is optimistic that this methodology can be further refined to enable the storage of single photons for significantly longer periods, potentially reaching many milliseconds, a crucial advancement for quantum networking.

Another monumental achievement highlighted in the study is the successful integration of multiple light cage memories onto a single chip, which was then housed within a cesium vapor cell. Crucially, subsequent measurements revealed that different light cages, all fabricated with identical designs, exhibited nearly identical storage performance across two distinct devices situated on the same chip. This extraordinary level of consistency is an indispensable prerequisite for the development of truly scalable quantum systems, where uniformity and predictability are paramount.

The remarkable reproducibility observed in these experiments can be directly attributed to the exceptional precision afforded by the 3D-nanoprinting fabrication process. The researchers reported that variations within a single chip were meticulously controlled to be less than 2 nanometers, while the differences between entirely separate chips remained astonishingly below 15 nanometers. Such stringent control over fabrication tolerances is absolutely critical for enabling spatial multiplexing, a sophisticated technique that holds the potential to dramatically augment the number of quantum memories operating in parallel on a single device, thereby boosting computational power and communication capacity.

Profound Implications for Quantum Networks and Computing

The development of light cage quantum memories directly addresses several long-standing and formidable challenges that have hindered the progress of quantum technologies. Within the context of quantum repeater networks, these advanced memories are poised to synchronize multiple single photons simultaneously, a capability that will substantially enhance the efficiency and robustness of long-distance quantum communication. Furthermore, in the realm of photonic quantum computing, these memories provide essential controlled delays, a fundamental requirement for implementing feed-forward operations in measurement-based quantum computing architectures, which are increasingly seen as a promising avenue for building powerful quantum computers.

Beyond their performance advantages, the light cage platform distinguishes itself through its remarkable practicality. Unlike many competing quantum memory technologies that necessitate cryogenic cooling or complex atomic-trapping apparatus, this system operates comfortably slightly above room temperature. This operational characteristic significantly simplifies deployment and reduces the overall infrastructure requirements, while simultaneously offering a higher bandwidth per memory mode. The ability to reliably produce a multitude of identical quantum memories on a single chip presents a clear and accelerated pathway toward the realization of large-scale quantum photonic integration, a critical step in miniaturizing and commercializing quantum technologies.

The inherent flexibility of the fabrication process also opens up exciting possibilities for combining light cage quantum memories with existing photonic infrastructure. This technology can potentially be seamlessly integrated with direct fiber coupling and other established photonic components, further accelerating its adoption and utility. These combined advantages strongly position light cage quantum memories as a leading contender for forming the backbone of future quantum communication networks, promising unprecedented levels of security and computational power.

A Scalable and Promising Future Trajectory

In summation, the creation of light cage quantum memories represents a monumental stride in the field of quantum photonic research. By masterfully merging the sophistication of advanced 3D-nanoprinting techniques with the fundamental principles of quantum optics, the researchers have successfully engineered a compact, highly scalable, and remarkably practical system. This innovative technology is poised to significantly accelerate the arrival of robust and functional quantum networks and to pave the way for the development of substantially more powerful and versatile quantum computers, ushering in a new era of technological advancement.