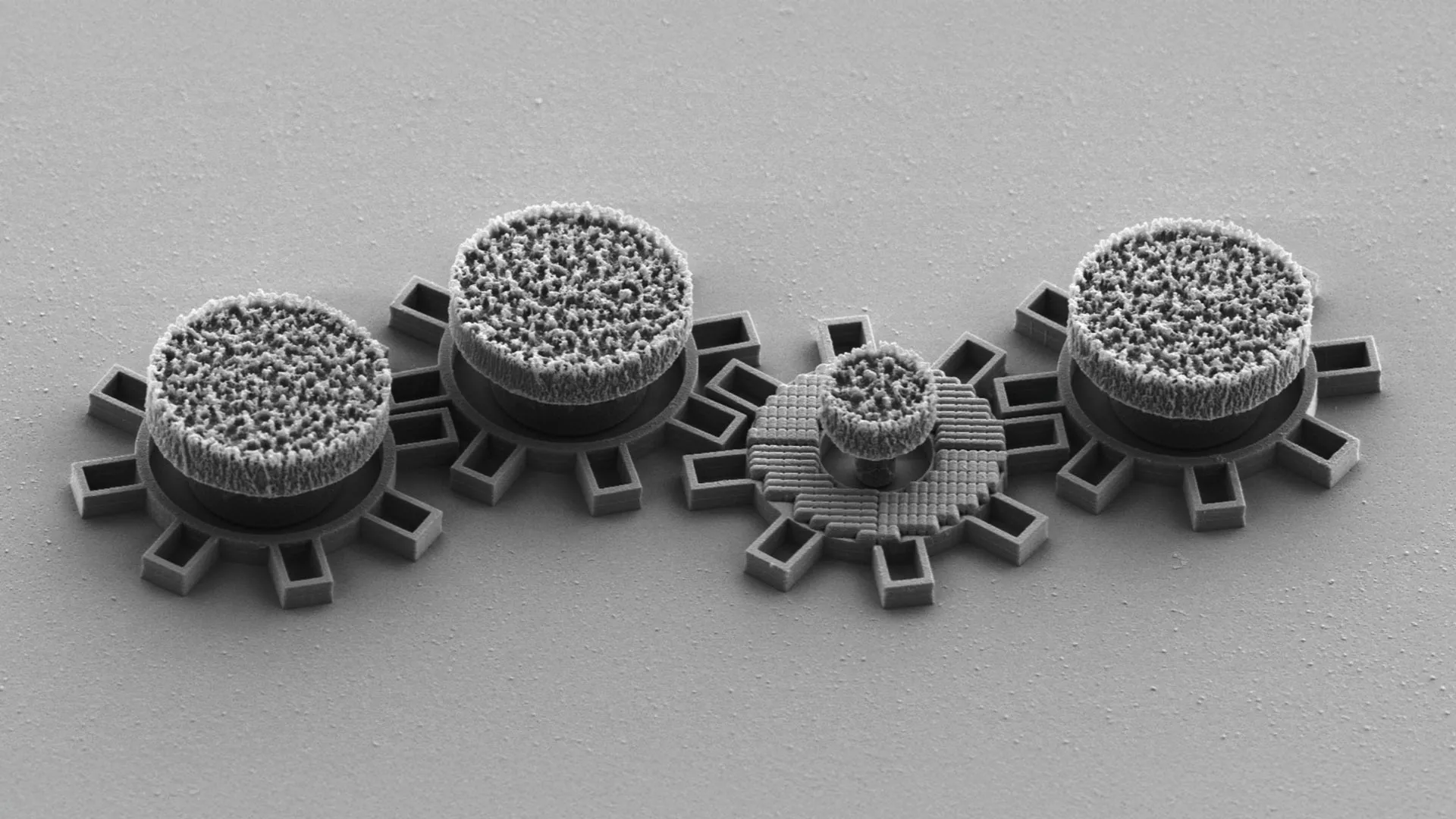

Researchers at the University of Gothenburg have achieved a groundbreaking feat in nanotechnology, successfully constructing light-powered gears on a micrometer scale. This remarkable development signifies a pivotal moment, as it promises to enable the creation of the smallest on-chip motors ever conceived, with the potential to be integrated within the diameter of a single human hair. The implications of this breakthrough are vast, potentially ushering in a new era of micro-robotics and precision engineering.

Gears, fundamental components in countless mechanical systems, from intricate timepieces and robust automobiles to sophisticated robots and colossal wind turbines, have long been the subject of intense research aimed at miniaturization. For over three decades, scientists have strived to engineer gears of ever-decreasing size to build micro-engines. However, progress had plateaued at a size of 0.1 millimeters, primarily due to the insurmountable challenge of constructing the necessary drive trains that could impart motion to components of such minuscule dimensions. The intricate linkages and mechanical connections that power larger gears simply could not be scaled down effectively without losing functionality.

The team at the University of Gothenburg, alongside collaborators, has now shattered this long-standing barrier. Their innovative approach fundamentally diverges from traditional mechanical drive trains. Instead, they have harnessed the power of laser light, employing it to directly set the gears in motion. This paradigm shift eliminates the need for complex and fragile mechanical couplings, which were the Achilles’ heel of previous miniaturization efforts.

Gears Powered by Light: A Novel Mechanism

The core of this revolutionary technology lies in the use of optical metamaterials. In their recent study, the researchers demonstrate that microscopic machines can be propelled by these advanced materials. Optical metamaterials are ingeniously designed small, patterned structures that possess the extraordinary ability to capture and precisely control light at the nanoscale. Utilizing established lithography techniques, the researchers have successfully manufactured gears incorporating these optical metamaterials. These gears are fabricated from silicon, directly onto a microchip, with individual gear wheels boasting diameters ranging from a few tens of micrometers.

The mechanism for actuation is elegantly simple yet profoundly effective. By directing a laser beam onto the metamaterial integrated within the gear, the researchers can induce rotation. The intensity of the laser light serves as a direct controller of the gear’s rotational speed. Furthermore, the direction of the gear’s spin can be altered by simply changing the polarization of the incident light. This level of precise control over microscopic motion, driven by light, is unprecedented.

This breakthrough brings the realization of functional micromotors tantalizingly close. The ability to create these light-powered gears is the crucial step towards building self-contained, microscopic engines capable of performing work.

A New Way of Thinking About Microscale Mechanics

"We have built a gear train in which a light-driven gear sets the entire chain in motion," explains Gan Wang, the study’s first author and a researcher in soft matter physics at the University of Gothenburg. "The gears can also convert rotation into linear motion, perform periodic movements and control microscopic mirrors to deflect light." This versatility highlights the potential of these light-powered systems to perform a range of complex tasks at the microscale.

The profound significance of this research lies in its ability to integrate such sophisticated microscopic machines directly onto a microchip and power them with light. This integration, coupled with the ease of light control, unlocks entirely new possibilities that were previously confined to the realm of science fiction. Since laser light does not necessitate any fixed physical contact with the machine and is inherently easy to manipulate, the micromotor concept can be scaled up to create highly complex and integrated microsystems.

"This is a fundamentally new way of thinking about mechanics on a microscale," Gan Wang emphasizes. "By replacing bulky couplings with light, we can finally overcome the size barrier that has held back progress for so long." This statement encapsulates the transformative nature of their discovery, signaling a departure from conventional engineering principles for micro-devices.

Approaching Cell Size: Medical and Beyond

With these remarkable advances, scientists are now envisioning micro- and nanomachines capable of intricate tasks such as controlling light with exceptional precision, manipulating minuscule particles with delicate accuracy, or being seamlessly integrated into the next generation of lab-on-a-chip systems. The dimensions of these gears are particularly noteworthy; a gear wheel can be as small as 16-20 micrometers in diameter. This size is comparable to that of many human cells, bringing the field of medicine within immediate reach of this technology.

"We can use the new micromotors as pumps inside the human body, for example to regulate various flows," Gan Wang elaborates. "I am also looking at how they function as valves that open and close." The potential for in-vivo applications is immense. Imagine microscopic pumps delivering medication precisely where needed within the bloodstream, or tiny valves controlling the flow of fluids in delicate biological tissues.

Beyond medical applications, these light-powered micromotors could revolutionize microfluidics, enabling the precise manipulation of fluids in lab-on-a-chip devices for diagnostics and research. They could also be employed in advanced manufacturing processes, assembling microscopic components or acting as tiny robotic arms for intricate tasks. The ability to control these devices wirelessly via light offers significant advantages in environments where physical access is limited or where sterile conditions are paramount.

The research also opens doors for advancements in optical computing and sensing. The capacity of these metamaterials to interact with light suggests potential for creating novel optical switches, modulators, or even microscopic sensors that respond to specific light wavelengths. The precise control over gear movement and their integration onto chips further enhance the prospects for building compact and efficient optical information processing systems.

The scalability of this technology is a critical factor for its widespread adoption. The researchers’ use of standard lithography techniques means that these micromotors can be manufactured using existing semiconductor fabrication processes, paving the way for mass production. This accessibility is crucial for transitioning from laboratory prototypes to real-world applications.

The challenges that remain include ensuring the long-term durability and reliability of these microscopic devices, particularly in harsh environments like the human body. Further research will focus on optimizing the metamaterial design for enhanced efficiency and exploring a wider range of actuation mechanisms. However, the fundamental principle has been proven, and the path forward is clear.

In conclusion, the development of light-powered micromotors by the University of Gothenburg team represents a paradigm shift in micro-engineering. By circumventing the limitations of traditional mechanical drive trains and embracing the precision of light, these scientists have not only built the smallest gears to date but have also laid the foundation for a new generation of microscopic machines with transformative potential across numerous scientific and industrial domains, most notably in medicine, where they promise to bring about revolutionary diagnostic and therapeutic capabilities. The era of microscopic robotics, driven by light and operating at scales previously unimaginable, has officially begun.